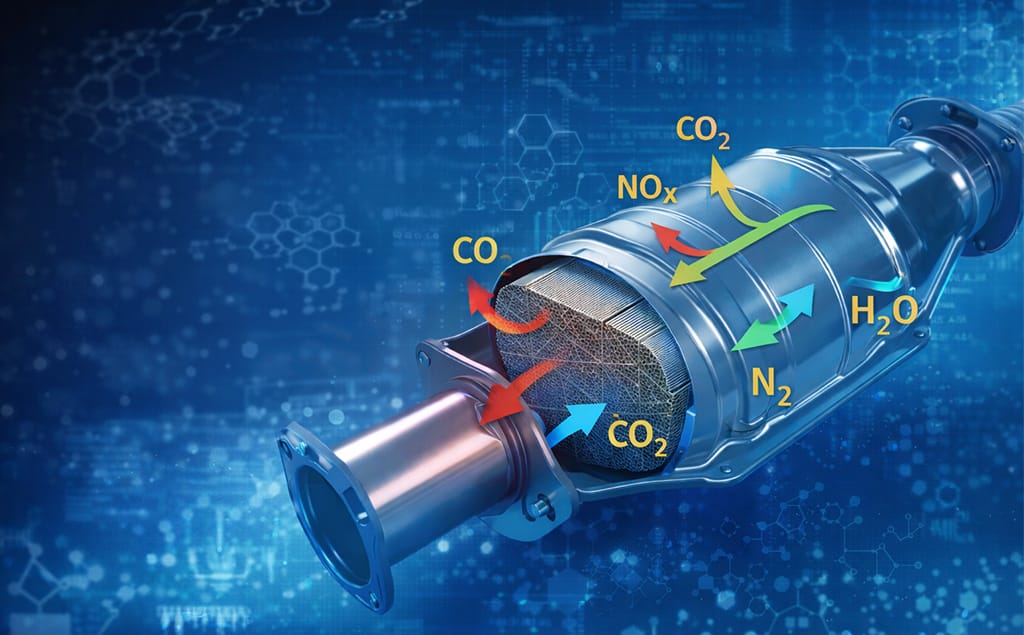

In catalytic converter design, the substrate material plays a crucial role in determining performance, durability, and cost. The two most common types are keramický a metallic substrates. This article compares them in terms of structure, thermal performance, backpressure, durability, cost, and applications — helping you decide which is the better fit for your needs.

1. Structure and Working Principle

- Ceramic substrates are typically made from cordierite, a low-expansion ceramic material, shaped into a honeycomb structure. The surface is coated with a plášť layer and impregnated with precious metals (Pt, Pd, Rh).

- Metallic substrates, on the other hand, are constructed from thin sheets of heat-resistant metal alloys (often FeCrAl). These foils are corrugated and rolled into a honeycomb shape, sometimes welded or brazed for added strength.

Both designs aim to provide a large surface area for catalytic reactions while maintaining optimal exhaust gas flow.

2. Thermal Response and Light-Off Performance

The catalytic converter only becomes fully effective once it reaches its teplota při zhasnutí světla — the point where emissions are efficiently converted.

- Metal substrates heat up faster due to higher thermal conductivity and lower heat capacity. They achieve light-off sooner, making them ideal for cold-start emission control.

- Ceramic substrates have higher thermal mass and slower heat transfer, so they take slightly longer to reach operating temperature.In short: for faster heat-up and early emissions reduction, metallic substrates have the upper hand.

3. Exhaust Flow and Backpressure

Low backpressure means better exhaust flow and improved engine performance.

- Metallic converters can be made with thinner walls and higher cell densities, allowing more open area for gas flow and lower backpressure.

- Ceramic converters usually have slightly thicker walls due to material strength limitations, resulting in marginally higher backpressure.

However, in real-world driving, the difference in flow resistance is often minimal for properly designed converters.

4. Durability and Thermal Shock Resistance

Durability under high temperatures and thermal cycling is a key performance factor.

- Ceramic substrates are highly resistant to corrosion and high heat but are brittle and prone to cracking under mechanical or thermal shock (rapid temperature changes).

- Metallic substrates are more flexible, better at handling vibration and thermal expansion, and have excellent shock resistance.

- However, metals may suffer from oxidace nebo material fatigue over long periods if not made from premium alloys.

Verdict: metallic substrates are generally more durable in harsh conditions, while ceramic ones are more stable under steady high-heat operation.

5. Cost and Manufacturing

- Ceramic converters are cheaper to manufacture. The material and forming processes are well-established and cost-efficient, which is why most OEMs still prefer ceramic for standard vehicles.

- Metallic converters are more expensive due to the cost of metal foils, precision forming, and brazing processes. However, they offer superior performance for demanding or performance-oriented applications.

6. Typical Applications

| Application Scenario | Recommended Type | Key Advantage |

|---|---|---|

| Close-coupled (near-engine) converter | Kov | Fast light-off, withstands high temperature |

| Underfloor main converter | Ceramic | Cost-effective, stable long-term performance |

| Performance / racing vehicles | Kov | Low backpressure, quick response |

| Standard mass-production vehicles | Ceramic | Proven technology, affordable production |

7. Future Trends and Hybrid Designs

Modern emission systems are moving toward hybrid or composite substrates to balance cost and performance. Examples include:

- Combining metallic pre-converters (for quick light-off) with ceramic main converters (for durability).

- Using pokročilé nátěry a thin-wall ceramics for better heat response.

- Research into nanostructured materials a new alloys continues to enhance efficiency and longevity.

8. Conclusion: Which One Is Better?

There’s no universal winner — the “better” catalytic converter depends on your priorities:

- For quick light-off, low backpressurea vibration resistance, go with metallic.

- For cost efficiency, high-temperature stabilitya mass production, choose keramický.

In general, ceramic substrates dominate OEM use, zatímco metallic converters are favored in performance and high-temperature environments.