Introduction

Every modern gasoline-powered vehicle contains a remarkable piece of chemical engineering hidden within its exhaust system. This device, the three-way catalytic converter, serves a single, crucial purpose: to neutralize the most harmful pollutants produced by an internal combustion engine. Without it, our cities would be choked with smog, and air quality would pose a significant threat to public health. The engine’s combustion process, while powerful, is imperfect. It generates toxic byproducts like carbon monoxide, unburned hydrocarbons, and nitrogen oxides. The three-way catalytic converter acts as a final line of defense. It transforms these hazardous gases into harmless substances before they ever reach the tailpipe. This article provides a scientific and technical exploration of the three-way catalytic converter. We will examine its history, its intricate chemical processes, its physical components, and the precise conditions required for it to function effectively.

Chapter 1: The Evolution from Two-Way to Three-Way Converters

The journey to the modern three-way catalytic converter began with a growing awareness of air pollution. In the mid-20th century, scientists and regulators identified vehicle exhaust as a primary source of urban smog. The first major legislative response in the United States was the Clean Air Act, which empowered the Environmental Protection Agency (EPA) to set strict limits on vehicle emissions.

The First Step: Two-Way Oxidation Converters

Automakers initially responded with the “two-way” catalytic converter. These devices first appeared on a widespread basis in the U.S. market on most 1975 model-year vehicles. Their job was to tackle two of the three main pollutants: carbon monoxide (CO) and unburned hydrocarbons (HC).

These early converters functioned as oxidation catalysts. Inside the device, oxygen from the exhaust stream reacted with CO and HC. This chemical reaction, accelerated by catalysts like platinum and palladium, converted them into two much safer compounds: carbon dioxide (CO₂) and water (H₂O). While effective at this specific task, two-way converters did nothing to address the third major pollutant: oxides of nitrogen (NOx). NOx is a key ingredient in the formation of acid rain and ground-level ozone.

The Comprehensive Solution: The Advent of the Three-Way Converter

As regulations tightened, the need for a more complete solution became urgent. Engineers developed the “three-way” converter to address all three classes of pollutants simultaneously. Volvo was a pioneer, introducing the first commercial three-way converters on its 1977 vehicles for the California market, which had the strictest emissions laws.

By the 1981 model year, federal regulations demanded significant reductions in NOx emissions. This mandate effectively made the three-way catalytic converter a standard and essential component on all new gasoline-powered cars in the United States. This technology represented a major leap forward, as it incorporated a second chemical process—reduction—alongside oxidation. This dual-action capability is what makes it “three-way.”

Comparison: Two-Way vs. Three-Way Catalytic Converters

The distinction between these two technologies is fundamental. The table below outlines their key differences. Modern vehicles exclusively use three-way converters to meet comprehensive global emissions standards.

| Característica | Two-Way Catalytic Converter | Three-Way Catalytic Converter |

|---|---|---|

| Pollutants Treated | Carbon Monoxide (CO), Hydrocarbons (HC) | Carbon Monoxide (CO), Hydrocarbons (HC), Nitrogen Oxides (NOx) |

| Primary Chemical Process | Oxidation | Oxidation and Reduction |

| Catalyst Metals Used | Platinum (Pt), Palladium (Pd) | Platinum (Pt), Palladium (Pd), Rhodium (Rh) |

| Función primaria | Converts CO to CO₂ and HC to CO₂ + H₂O | Performs the same oxidation reactions plus reduces NOx to N₂ |

| Modern Application | Obsolete in gasoline cars; used in some diesel and lean-burn applications | Standard on virtually all modern gasoline-powered vehicles |

Chapter 2: The Core Chemistry of a Three-Way Catalytic Converter

A three-way catalytic converter is essentially a chemical reactor. It uses specific materials, known as catalysts, to speed up chemical reactions without being consumed in the process. The “three-way” name signifies its ability to promote three simultaneous chemical transformations. These reactions are grouped into two distinct processes: reduction and oxidation.

These two processes occur in separate stages or on different catalyst materials within the converter housing. For both to work efficiently, the engine’s computer must maintain a very precise balance of fuel and air.

The Reduction Reaction: Neutralizing Nitrogen Oxides (NOx)

The first stage of conversion targets the most difficult pollutants, the nitrogen oxides (NOx). This family of gases forms when nitrogen and oxygen react under the high-pressure, high-temperature conditions inside an engine’s cylinders.

The reduction catalyst is responsible for breaking NOx apart. Rhodium (Rh) is the precious metal of choice for this task. It has a unique ability to strip oxygen atoms from nitrogen oxide molecules. This reaction frees the nitrogen atoms, which then bond with each other to form harmless nitrogen gas (N₂), the primary component of the air we breathe.

- Chemical Reaction: 2NOx → xO₂ + N₂

In this reaction, the rhodium catalyst facilitates the breakdown of NOx into elemental oxygen and stable nitrogen gas.

The Oxidation Reaction: Cleaning Up CO and HC

The second stage handles carbon monoxide (CO) and unburned hydrocarbons (HC). Carbon monoxide is a poisonous gas resulting from incomplete fuel combustion. Hydrocarbons are simply raw, unburned fuel particles.

The oxidation catalyst uses the oxygen freed during the reduction stage, along with any other available oxygen in the exhaust, to convert these two pollutants. Platinum (Pt) and Palladium (Pd) are the primary metals used for this process. They promote reactions that add oxygen to the CO and HC molecules.

- Carbon Monoxide Oxidation: 2CO + O₂ → 2CO₂

- Hydrocarbon Oxidation: CₓH₂ₓ₊₂ + [(3x+1)/2]O₂ → xCO₂ + (x+1)H₂O

This process transforms toxic carbon monoxide into non-toxic carbon dioxide (CO₂) and converts polluting hydrocarbons into carbon dioxide and water vapor (H₂O).

Summary of Chemical Transformations

The table below summarizes the input pollutants and their output products after passing through a three-way catalytic converter.

| Input Pollutant | Chemical Formula | Type of Reaction | Catalyst Metal | Output Product | Chemical Formula |

|---|---|---|---|---|---|

| Nitrogen Oxides | NOx | Reduction | Rhodium (Rh) | Nitrogen Gas | N₂ |

| Carbon Monoxide | CO | Oxidation | Platinum (Pt), Palladium (Pd) | Carbon Dioxide | CO₂ |

| Hydrocarbons | HC | Oxidation | Platinum (Pt), Palladium (Pd) | Carbon Dioxide & Water | CO₂ & H₂O |

Chapter 3: Anatomy of a Three-Way Catalytic Converter

While the chemistry is complex, the physical structure of a converter is designed for maximum efficiency and durability. It consists of three primary components working in unison: the substrate, the washcoat, and the catalyst layer.

The Substrate: A Foundation of Maximum Surface Area

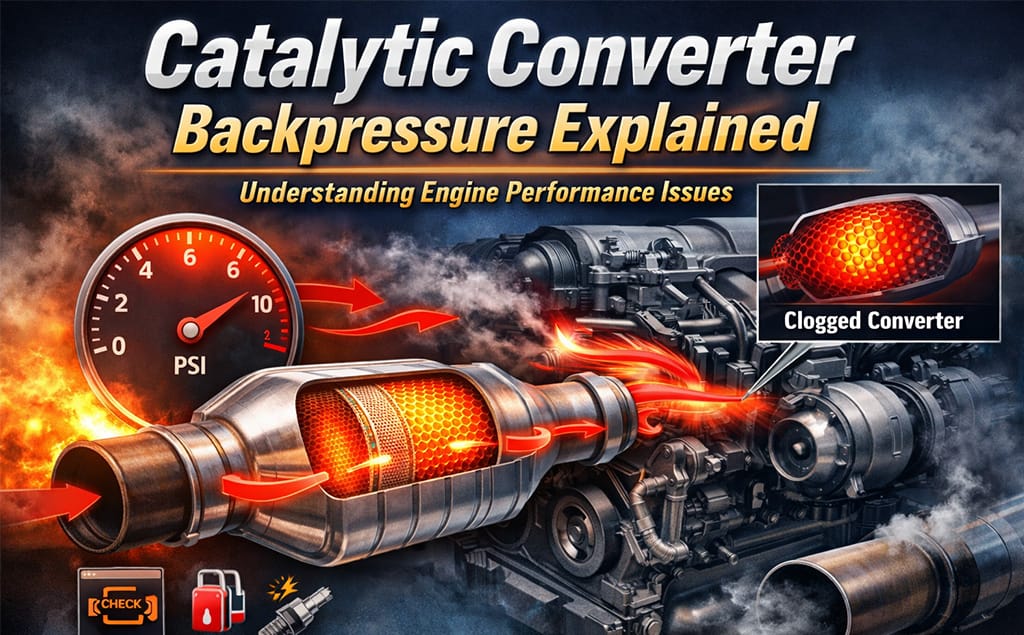

The core of the converter is the substrate. This is a ceramic monolith, typically made of cordierite, or sometimes a metallic structure. It is not a solid block but an intricate honeycomb structure. This design features thousands of tiny parallel channels.

The purpose of the honeycomb is to maximize the surface area that comes into contact with the exhaust gases. A larger surface area allows for more efficient and rapid chemical reactions within a compact physical space. The density of these channels, measured in cells per square inch (CPSI), can vary. High-performance applications may use a higher CPSI for better conversion, while standard vehicles use a balance of efficiency and flow.

The substrate material must possess several key characteristics:

- High-Temperature Resistance: It must withstand exhaust temperatures exceeding 1200°C (2200°F).

- Thermal Stability: It should not crack or deform under rapid temperature changes.

- Structural Strength: It must resist the constant vibrations and pressures of the exhaust system.

- Low Cost: Manufacturers must produce it economically on a mass scale.

The Washcoat: Increasing the Reactive Surface

The ceramic substrate itself is not catalytically active. To prepare it for the precious metals, manufacturers apply a “washcoat.” This is a layer of porous material, most commonly aluminum oxide (Al₂O₃), applied to the entire internal surface of the honeycomb structure.

The washcoat’s function is to dramatically increase the effective surface area at a microscopic level. Its rough, porous texture creates countless nooks and crannies where the catalyst particles can anchor. This increases the available reactive sites exponentially, making the converter far more efficient than if the metals were applied directly to the smooth ceramic.

The Precious Metals: The Catalytic Powerhouse

The final and most crucial layer contains the catalysts themselves. These are the precious metals from the platinum group: Platinum (Pt), Palladium (Pd), and Rhodium (Rh). A very thin layer of these metals is bonded to the surface of the washcoat.

- Platinum (Pt) is an excellent oxidation catalyst, highly effective at converting both CO and HC.

- Palladium (Pd) also serves as an oxidation catalyst and is often used as a lower-cost alternative or supplement to platinum.

- Rhodium (Rh) is the dedicated reduction catalyst. Its sole purpose is to break down NOx.

The high cost of these metals is the primary reason why three-way catalytic converters are valuable and a frequent target for theft. Automakers constantly research new ways to reduce the amount of precious metal needed (a process called “thrifting”) without sacrificing conversion efficiency.

Chapter 4: The Critical Conditions for Optimal Performance

A three-way catalytic converter does not operate at peak efficiency under all conditions. Two factors are absolutely critical for its function: the air-fuel ratio and the operating temperature. The vehicle’s engine management system is meticulously designed to control these two variables.

The Stoichiometric Air-Fuel Ratio: A Delicate Balance

For the converter to perform both reduction and oxidation reactions effectively, the engine must operate at or very near the stoichiometric air-fuel ratio. For gasoline, this ratio is approximately 14.7 parts air to 1 part fuel by mass (14.7:1).

- If the mixture is too rich (too much fuel), there will not be enough oxygen available to oxidize the CO and HC completely.

- If the mixture is too lean (too much air), the excess oxygen will inhibit the reduction of NOx, as the rhodium catalyst will not be able to effectively strip oxygen from the NOx molecules.

The “sweet spot” for a three-way catalytic converter is a very narrow window around this stoichiometric point. To maintain this balance, vehicles use a closed-loop feedback system. Oxygen sensors (or O2 sensors) placed in the exhaust stream before and after the converter constantly measure the oxygen content. This data is fed back to the engine control unit (ECU), which makes real-time adjustments to the fuel injection to keep the air-fuel ratio perfectly balanced.

The Light-Off Temperature: The Need for Heat

Catalysts require a minimum temperature to become chemically active. This is known as the “light-off” temperature, which is typically between 250°C and 300°C (482°F to 572°F). Below this temperature, the converter does very little to clean the exhaust.

This is why a vehicle’s emissions are highest during a “cold start.” When the engine first starts, the exhaust and the converter are cold. It can take several minutes of driving for the converter to reach its light-off temperature. During this warm-up period, untreated pollutants pass directly out of the tailpipe.

To combat this problem, engineers have developed several strategies:

- Close-Coupled Catalysts (CCC): This involves placing a smaller, preliminary catalytic converter much closer to the engine’s exhaust manifold. Being closer to the heat source allows it to reach light-off temperature much faster, often in under 20 seconds.

- Electrically Heated Catalysts (EHC): Some advanced systems use an electric heating element to preheat the converter before or immediately after the engine starts. This can significantly reduce cold-start hydrocarbon emissions.

Chapter 5: Broader Impact and Modern Applications

El three-way catalytic converter is more than just a component in a car; it is a foundational technology for global environmental protection. Its widespread adoption has been directly responsible for massive reductions in air pollution in cities across the world.

Beyond standard passenger cars, this technology is adapted for a wide range of applications that use internal combustion engines. This includes:

- Trucks and buses

- Motorcycles

- Forklifts and mining equipment

- Electrical generators

- Locomotives and marine vessels

- Even some advanced wood-burning stoves to control particulate and gas emissions

In each case, the core principles of three-way catalysis are adapted to meet specific regulations and operating conditions. The ongoing advancement of this technology is driven by progressively stricter emissions standards, such as the Euro standards in Europe and the Tier standards set by the EPA in the United States.

Conclusion

El three-way catalytic converter is an unsung hero of modern automotive technology. It is a sophisticated chemical processing plant in miniature, performing a complex ballet of reduction and oxidation reactions. By harnessing the power of platinum, palladium, and rhodium, it transforms a toxic stream of engine exhaust into largely benign gases. Its development was a direct and effective response to a growing environmental crisis. While the future of transportation may lie with electric vehicles, the internal combustion engine will remain prevalent for decades to come. As long as it does, the continuous improvement and application of the three-way catalytic converter will be essential for protecting the air we breathe and the health of our planet.