Perkenalan

The catalytic converter has been one of the most critical innovations in automotive emissions control since the 1970s. As global regulations tighten and drivers pursue both performance and efficiency, the konverter katalitik tiga arah Dan konverter katalitik aliran tinggi have become essential technologies for balancing power, environmental responsibility, and vehicle compliance.

While the standard konverter katalitik tiga arah is designed to reduce hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) simultaneously, the high flow version seeks to achieve the same chemical conversions with minimal restriction to exhaust gases. This balance between clean emissions and optimal performance remains one of the most discussed topics among enthusiasts, engineers, and tuners alike.

This article explains the science, function, materials, pros, and limitations of both converter types. It also discusses performance data, durability factors, and brand comparisons to help you choose the most suitable catalytic converter for your specific application.

1. Understanding the Three Way Catalytic Converter

Itu konverter katalitik tiga arah (TWC) is the cornerstone of modern vehicle emissions control. It’s called “three way” because it handles three pollutants simultaneously:

- Oksidasi karbon monoksida (CO) into carbon dioxide (CO₂)

- Oksidasi hidrokarbon (HC) into carbon dioxide and water

- Pengurangan nitrogen oksida (NOx) into nitrogen and oxygen

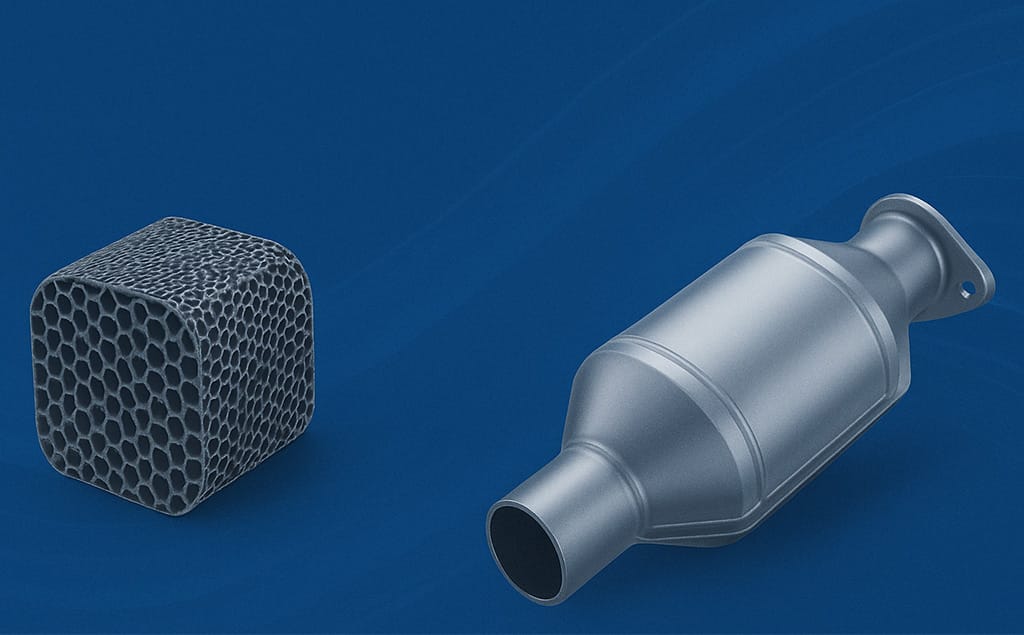

This chemical reaction occurs on a ceramic or metallic substrate coated with precious metals such as platinum (Pt), paladium (Pd), dan rodium (Rh). These metals act as catalysts—substances that accelerate chemical reactions without being consumed.

When exhaust gases pass through the converter, these reactions take place rapidly under high temperatures, converting toxic pollutants into harmless gases. A properly functioning TWC can achieve conversion efficiencies above 90%, depending on the air-fuel ratio and catalyst temperature.

2. High Flow Catalytic Converters: Balancing Power and Compliance

A konverter katalitik aliran tinggi performs the same function as a traditional unit but with a less restrictive internal design. It uses a substrate with larger cells per inch (CPSI) and thinner walls to allow gases to flow more freely. This results in reduced back pressure, helping engines breathe better, especially in performance or modified vehicles.

High flow cats are popular among racing enthusiasts and tuners who want to retain emissions control while optimizing horsepower and torque. However, the trade-off is that efficiency in reducing emissions can slightly decrease, especially at low operating temperatures.

Comparison Table: Standard vs. High Flow Catalytic Converter

| Fitur | Standard Three Way Converter | High Flow Converter |

|---|---|---|

| Substrate Density | 400–600 CPSI | 100–300 CPSI |

| Flow Restriction | Sedang hingga Tinggi | Rendah |

| Power Output | Stock-level | Improved (3–8% gain) |

| Pengendalian Emisi | Excellent | Good to Very Good |

| Daya tahan | Long-lasting | Depends on use/tuning |

| Ideal Application | Daily drivers | Modified or tuned engines |

| Cost Range | $150–$400 | $100–$600 |

3. How Three Way Catalysts Work in Real Driving Conditions

The converter’s efficiency depends on temperature, exhaust composition, and the vehicle’s rasio udara-bahan bakar. The ideal stoichiometric ratio for gasoline engines is 14.7:1, meaning 14.7 parts of air for every part of fuel.

When this balance is achieved, the TWC operates most effectively. Modern vehicles use oxygen sensors (O₂ sensors) before and after the converter to maintain this ratio. If the mixture is too rich or too lean, emissions increase, and the converter’s performance drops.

In modified engines or turbocharged setups, excess unburned fuel can enter the exhaust system. This can overheat and damage the converter’s core, especially in high flow catalytic converters, which use thinner walls that can melt under extreme temperatures.

4. Materials and Design Innovations

Manufacturers constantly improve materials to enhance performance and durability.

- Ceramic substrates offer thermal stability and are cost-effective.

- Metallic substrates (stainless or Inconel) resist vibration and thermal shock better.

- Washcoat technology has evolved, allowing more uniform dispersion of catalysts for greater efficiency.

Modern TWCs also integrate OBD2 compliance—the system that monitors converter performance and triggers the check engine light (P0420 code) if efficiency drops. Some high flow cats can trigger this code because their design produces slightly different readings compared to stock units.

5. Why Some Catalytic Converters Fail Prematurely

A common concern among vehicle owners is catalytic converter failure. Several reasons can explain this:

- Campuran bahan bakar yang kaya – unburned fuel ignites inside the converter, overheating it.

- Oil consumption – burned oil leaves ash deposits that clog the honeycomb structure.

- Engine misfire – raw fuel enters the exhaust and burns inside the converter.

- Flame tunes and backfires – popular in performance tuning, but they destroy the catalyst substrate.

Drivers who use aggressive “pop and bang” or “flame” tunes often report shortened converter lifespan, regardless of brand quality. This is not due to poor manufacturing but rather misuse under extreme combustion conditions.

6. Comparing Popular Brands

The market offers many catalytic converter brands, each with specific strengths.

- MagnaFlow: Known for precision manufacturing, stainless steel construction, and straight-through high-flow designs.

- Walker: Offers reliable OEM-grade converters with excellent fit and long-term durability.

- G-Sport (OBD2): Widely used in motorsports for its tough, high-temperature resistance and easy installation.

- Flowmaster: Once popular, but many users report inconsistent quality or reduced lifespan under performance conditions.

Comparison Table: Recommended Three Way and High Flow Brands

| Merek | Jenis | Bahan | OBD2 Compatibility | Ideal Use |

|---|---|---|---|---|

| MagnaFlow | High Flow | Baja Tahan Karat | Ya | Street/Track |

| Walker | Three Way | Ceramic | Ya | Daily Drivers |

| G-Sport | OBD2 | Metallic | Ya | Race/Performance |

| Flowmaster | High Flow | Ceramic | Partial | Budget Performance |

7. Legal and Environmental Considerations

Before purchasing a converter, always check local and federal emissions regulations. In the U.S., Dewan Sumber Daya Udara California (CARB) has the strictest standards. Using a non-compliant high flow catalytic converter in such states can result in fines or failed inspections.

Meanwhile, regions without strict emissions testing often allow universal or high flow cats as long as they don’t produce visible smoke or foul odors.

To remain eco-conscious while enjoying performance, choose EPA or CARB-certified converters and ensure your vehicle’s engine is well-tuned.

8. Installation Tips for Longevity

Proper installation and maintenance dramatically influence converter lifespan.

- Menggunakan high-quality welds or clamps to prevent exhaust leaks.

- Check for engine misfires or oil burning before installation.

- Warm up your engine gradually after installation to allow the substrate to settle.

- Avoid aggressive flame maps or over-rich tuning.

A well-installed converter, even a high flow one, can last 5–10 years with proper engine maintenance.

9. Common Myths About High Flow Converters

- “High flow cats always increase horsepower.” Not always. Gains depend on the engine setup and exhaust design.

- “You don’t need a cat for performance cars.” Modern racing cats provide low restriction while keeping emissions within safe limits.

- “All high flow converters fail quickly.” Cheap, poorly tuned setups cause failure—not the concept itself.

10. Emerging Technologies in Catalyst Design

Recent developments include nanoparticle catalysts, electrically heated converters, Dan smart sensors that adjust reactions dynamically. These innovations aim to improve cold-start emissions, one of the most challenging phases for conventional converters.

The future may bring hybrid catalytic systems that combine oxidation and reduction zones with advanced temperature sensors to maintain optimal conditions across all driving modes.

11. Added Section – The Role of the Three Way Catalytic Converter in Hybrid and EV Transition

While electric vehicles (EVs) may eventually eliminate exhaust systems entirely, millions of hybrid and gasoline cars will still depend on konverter katalitik tiga arah for decades. Hybrid cars often operate their engines intermittently, which means the converter must heat up quickly and resist repeated thermal cycling. Manufacturers now use thin-wall metallic substrates and advanced washcoats to improve light-off time and stability.

12. Added Section – Choosing Between High Flow and Three Way Converters

When deciding between a konverter katalitik tiga arah dan sebuah high flow converter, consider your goals:

- Performance Priority → Choose a high flow converter with OBD2 compliance.

- Reliability and Emissions Priority → Opt for a traditional TWC with higher cell density.

- Budget Builds → Mid-range high flow units can offer both performance and legality if tuned properly.

Ultimately, both types share the same purpose—to reduce harmful emissions—but differ in how they balance environmental compliance and exhaust flow dynamics.

Kesimpulan

Itu konverter katalitik tiga arah remains one of the most effective emissions control devices ever invented, while the konverter katalitik aliran tinggi serves as its performance-oriented evolution. Selecting the right type depends on your engine setup, emission requirements, and driving style.

Always remember: even the best converter cannot compensate for poor engine health or bad tuning. With proper installation, brand choice, and maintenance, these devices can last years while ensuring your vehicle performs efficiently and responsibly.

Whether your goal is maximum performance or regulatory compliance, understanding the science behind catalytic converters empowers you to make smarter, cleaner, and more sustainable automotive choices.