A concise guide for procurement and engineering teams on light-off behavior in modern convertitori catalitici a tre vie. This article explains why the light-off phase matters for emission performance, how exhaust temperature management, catalyst formulation, and system design affect warm-up, and what U should consider when specifying a solution for fleet or OEM projects.

What is light-off and why does it matter for the catalytic converter?

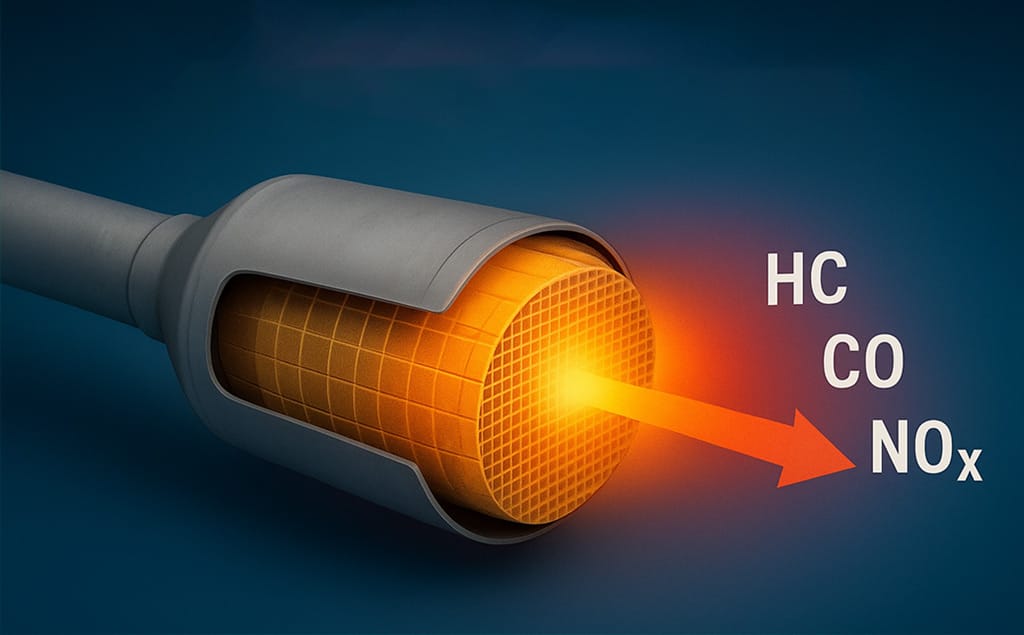

Light-off describes the moment a catalyst becomes active enough to convert harmful components of automobile exhaust into less harmful products. For an OEM or fleet purchaser, the light-off window is critical because a significant share of vehicle emission occurs during cold start. A properly designed catalytic converter must achieve useful conversion quickly to meet emission regulations and to reduce vehicle emission in real-world driving.

The three-way catalyst inside the catalytic converter performs simultaneous oxidation and reduction reactions—oxidation of carbon monoxide and hydrocarbons and reduction of nitrogen oxides—so early activation reduces hc and carbon monoxide. Understanding the thermodynamics and kinetics of the catalytic conversion helps U specify a catalyst system that minimizes cold-start emissions.

How does exhaust temperature influence light-off in a three-way catalytic converter?

Exhaust temperature is the most important variable for light-off. The catalytic converter requires sufficient exhaust temperature to drive the catalytic reaction and maintain oxidation efficiency. During cold start the exhaust temperature is low, so the catalyst surface remains below light-off temperature and conversion is limited.

Managing exhaust temperature through downstream insulation, shorter catalyst distance from the exhaust manifold, or targeted heat-retention converter features improves warm-up rates. Design choices that influence exhaust flow and heat transfer will directly affect how fast a three-way catalytic converter reaches operating temperature.

What role does catalyst formulation (platinum, palladium, rhodium) play in light-off?

Catalyst formulation uses precious metal loadings—typically platinum, palladium and rhodium—to enable efficient conversion at lower temperatures. The relative proportions of those precious metal components determine activity, selectivity and durability for different pollutant streams.

Optimized washcoat and catalytic coating techniques can improve dispersion and increase activity at low temperatures. For procurement, specifying the right precious metal strategy balances cost and early light-off performance; higher platinum or palladium content and engineered rhodium sites often speed up activation.

How does exhaust flow and exhaust manifold design affect warm-up?

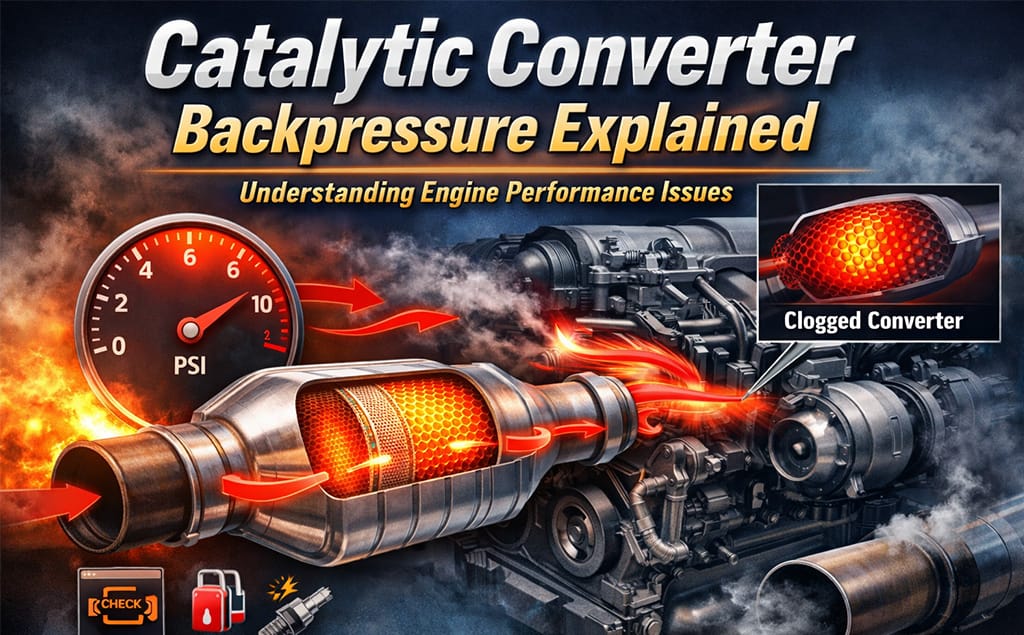

Exhaust flow characteristics from the exhaust manifold to the converter influence residence time, pressure drop and temperature distribution across the honeycomb structure. A well-designed exhaust manifold reduces mixing losses and ensures uniform exhaust gas contact with the catalyst surface for consistent light-off across the monolith.

High flow velocity can drop local temperatures and delay light-off in portions of the converter, while large converters with high cells per square inch reduce back-pressure but may need more heat to activate. Understanding exhaust flow and manifold routing lets U choose a converter that minimizes cold-start conversion loss.

Can electrically heated catalyst and thermal management reduce light-off time?

Electrically heated catalyst modules and downstream thermal management are proven approaches to shorten light-off time. An electrically heated catalyst raises the catalyst surface temperature rapidly after engine start, moving the system through the light-off window before most cold-start emissions occur.

Thermal insulation, close-coupled converter placement and heat shields also maintain exhaust temperature. Combining electrically heated catalyst elements with an optimized catalyst converter design provides a practical route to reduce harmful emissions during the critical minutes after start.

What measurements and sensors are used to assess light-off behavior?

Key measurements include exhaust temperature mapping, tailpipe emissions monitoring, and in-situ sensor feedback. An oxygen sensor upstream and downstream of the converter gives input to the control system and allows assessment of when the catalyst reaches operational conversion efficiency.

Portable emission measurement systems and dynamometer cold-start cycles are industry-standard tests to capture the light-off curve for HC, CO and NOx. Data from sensors and test rigs help engineers validate that a three-way catalytic converter meets performance targets under varying exhaust conditions.

How do fuel type and engine calibration affect light-off and pollutant conversion?

Fuel type and engine calibration influence how quickly the exhaust reaches temperatures needed for efficient oxidation and reduction. Gasoline blends, cold-rich operation and transient fueling can change the concentration of hc, gas and oxygen in the exhaust stream, impacting light-off.

Tuning engine start strategies such as ignition timing, cold enrichment and restart management can improve early catalytic conversion. In hybrid applications, exhaust temperature management is especially important because internal combustion engine on/off cycles change the thermal state of the aftertreatment.

How does aging, poisoning and thermal degradation change light-off performance?

Aging, thermal sintering and poisoning (for example sulfur or phosphorus deposition) degrade catalyst activity and slow light-off over service life. Hydrothermal aging redistributes precious metal particles and reduces available catalyst surface, lowering low-temperature activity.

Robust washcoat chemistry and protective converter features can extend useful life and maintain light-off performance. Lifecycle considerations should be part of procurement specifications to ensure long-term compliance with emission targets and to avoid premature replacement costs.

What test methods and regulations define acceptable light-off performance?

Regulatory tests and real-world driving emissions both influence how OEMs and suppliers design light-off behavior into systems. Emission regulations such as cold-start limits define acceptable HC and CO output in the initial minutes of engine operation.

Standardized tests—lab dynamometer cycles and vehicle certification procedures—provide objective measurements of light-off temperature and conversion. Understanding these procedures helps U choose converter features that align with compliance priorities and fleet performance goals.

How to specify converter features and system integration for faster light-off?

When specifying converter features, focus on close-coupled placement, optimized washcoat, fast light-off catalysts and options like electrically heated catalyst modules. Consider catalyst converter dimensions, substrate type (metal vs ceramic) and honeycomb structure to balance back-pressure and warm-up speed.

Integration into the exhaust system, sensor locations and engine calibration must be coordinated so the entire catalyst system minimizes cold-start pollutant output. Supplier documentation should include light-off curves, aging data and tests that confirm the specified performance under typical operating cycles.

Summary — What U should remember

- Key metrics: light-off temperature, time-to-50% conversion, and cold-start HC/CO output.

- Design levers: catalyst formulation, close-coupled placement, substrate selection and exhaust routing.

- Advanced options: electrically heated catalyst, thermal insulation and active engine strategies.

- Lifecycle: specify aging tests, poisoning resistance and replacement criteria.

- Procurement: require light-off curves, material declarations for precious metal content and validation data.