giriiş

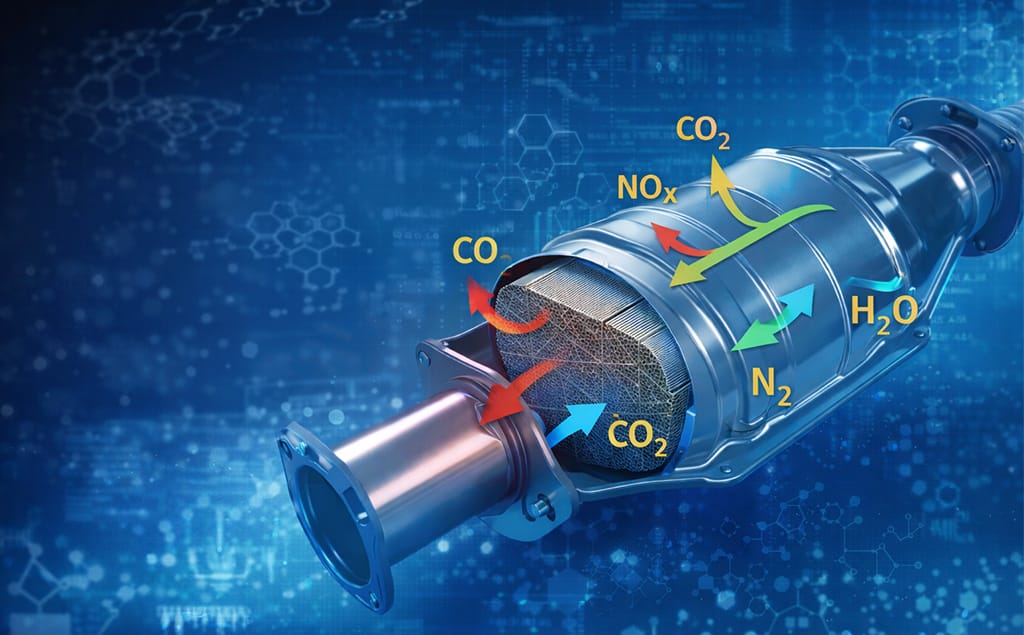

A üç yollu katalitik konvertör plays a central role in modern exhaust purification systems. It removes harmful pollutants and stabilizes engine performance by processing hydrocarbons, carbon monoxide, and nitrogen oxides. However, improper installation practices and engine-related faults continue to cause premature converter damage. Many vehicle owners assume a catalytic converter will last the entire life of the vehicle because it contains no moving parts. In reality, the converter interacts continuously with exhaust gases and the engine’s combustion process. When upstream systems fail, the converter becomes vulnerable. This article explains common installation mistakes and mechanical issues that lead to converter failure. It also examines how torque converters in automatic transmissions encounter related issues.

Installation Errors That Affect Converter Reliability

Technicians must install converters correctly to preserve exhaust efficiency. Incorrect seating, misalignment, and careless handling can shorten the operational life of both torque converters and catalytic converters. The risk rises when installers rush or ignore basic checks. The following sections explore major sources of failure.

Improper Seating of Torque Converters

A torque converter must fit securely onto the transmission input shaft. If a technician forces the converter into position, it can damage both the converter and the transmission pump. Installers must listen for the sequence of engagement sounds, usually described as clicks or pops. These signals confirm that the converter has locked into its recesses. When seating is incomplete, the converter may push against the flexplate during installation. This situation increases stress on the pump, raises operating temperatures, and accelerates internal wear.

Contaminated or Incorrect Transmission Fluid

Automatic transmissions depend on exact fluid chemistry. When installers add an incorrect fluid type, friction levels change. This disrupts converter lock-up behavior and raises heat generation. Contaminants in old or degraded fluid create further challenges. Small metallic particles, worn clutch material, and degraded additives can block passages or damage converter fins. Contamination also affects lubrication quality. As lubrication declines, internal stress rises, resulting in premature failure.

Coolant Intrusion into Transmission Fluid

A transmission cooler located inside the radiator can leak and release coolant into the transmission. When coolant mixes with transmission fluid, it rapidly weakens the converter. The mixture forms a thickened substance that reduces pressure and flow. This condition triggers overheating and loss of hydraulic stability. Coolant intrusion progresses quickly, making early detection essential. Drivers may notice shifting irregularities, delayed engagement, or unexpected transmission noise.

Electrical Connection Errors

Modern transmissions rely on precise communication between sensors, wiring harnesses, and the control unit. Installers must reconnect each harness securely. Loose or misconnected plugs disrupt the signals that control torque converter clutch engagement. This communication failure produces erratic behavior such as harsh shifts or slipping. Automotive specialists consistently emphasize the role of proper electrical reconnection as part of converter installation. A stable electrical pathway ensures that the converter operates with correct timing and load response.

Incorrect Stall Speed Selection

Selecting a torque converter with the wrong stall speed creates long-term heat stress. A higher stall speed generates excess heat during acceleration. A lower stall speed may prevent the engine from reaching an optimal torque range. In both cases, heat builds up faster than the system can dissipate it. Over time, this leads to fluid breakdown and internal deformation.

Engine Problems That Cause Catalytic Converter Damage

A üç yollu katalitik konvertör fails most often due to upstream engine problems rather than the converter itself. The converter processes exhaust continuously, so contaminants have immediate effects. The following engine conditions represent the most frequent sources of catalytic converter failure.

Engine Misfires and Unburned Fuel

Misfires cause raw fuel to enter the exhaust stream. Because the catalytic converter operates at high internal temperatures, unburned fuel can ignite inside the converter. This creates hotspots that melt the ceramic honeycomb structure. Overheating also breaks down the precious metal coatings responsible for emission reduction. Once the substrate melts, airflow becomes restricted and converter efficiency drops to near zero.

Oil or Coolant Leaks Entering the Exhaust

Engines with worn seals, damaged gaskets, or deteriorated piston rings may burn oil or coolant. These contaminants travel through the exhaust system and enter the converter. When oil burns on the converter surface, it forms thick carbon deposits. These deposits block airflow and cover catalytic metals, reducing conversion efficiency. Coolant contamination produces similar effects. Both conditions increase exhaust pressure and may cause backflow.

Incorrect Engine Timing

Engine timing affects combustion stability. When timing is incorrect, the engine may fail to burn fuel completely. This results in unburned hydrocarbons entering the exhaust, similar to a misfire event. The converter responds by overheating and eventually deteriorating. Modern engines rely on precise timing control, making regular inspections essential.

Faulty Oxygen Sensors and Air-Fuel Ratio Errors

Oxygen sensors determine the correct air-fuel mixture. A damaged sensor produces incorrect readings, causing the engine control module to enrich or lean out the mixture. A rich mixture sends excess fuel to the converter, while a lean mixture produces excess heat. Both conditions weaken the converter over time.

Undercarriage Damage

Physical damage to the converter can occur when a vehicle hits road debris, rocks, or deep potholes. A strong impact may crack the converter shell or distort the internal structure. Undercarriage strikes also damage mounting points, causing vibrations and leaks. These structural problems reduce emission efficiency and accelerate heat stress.

Improper Catalytic Converter Installation

Incorrect installation introduces mechanical stress that shortens converter life. Misalignment causes leaks, vibration, and reduced exhaust flow. Some installers may over-tighten clamps or bolts, deforming the converter shell. In severe cases, tools or jacks may damage the converter during handling.

Additional Factors Affecting Converter Longevity

Thermal Shock and Rapid Temperature Changes

A converter expands when heated. Rapid cooling from puddle splashes or cold-weather startup conditions creates thermal shock. This temperature swing may crack the ceramic substrate.

Fuel Additives and Low-Quality Fuel

Some additives generate residue that clogs the converter. Poor fuel quality accelerates carbon buildup. Engines running low-grade fuel produce unstable combustion patterns, which reduce converter lifespan.

Comparative Table of Common Converter Failure Causes

| Failure Cause | Affects Torque Converter | Affects Catalytic Converter | Mechanism |

|---|---|---|---|

| Improper seating | ✔ | ✘ | Mechanical stress and pump damage |

| Misfires/unburned fuel | ✘ | ✔ | Overheating and ceramic melting |

| Oil contamination | ✔ | ✔ | Lubrication loss or carbon deposits |

| Coolant intrusion | ✔ | ✔ | Thickened fluid or soot buildup |

| Electrical errors | ✔ | ✘ | Control signal disruption |

| Undercarriage damage | ✘ | ✔ | Physical impact and deformation |

Extended Discussion: Why Prevention Matters

Regular engine maintenance protects the üç yollu katalitik konvertör from unnecessary stress. Technicians should monitor spark plug condition, fluid levels, and sensor outputs. Vehicle owners should address warning lights promptly. Delaying repairs increases the chance of exhaust contamination and converter damage. Proper installation practices also play a major role. Installers must follow torque specifications, secure all connections, and verify alignment.

Çözüm

A üç yollu katalitik konvertör delivers reliable emission control only when the surrounding systems function correctly. Installation mistakes, engine misfires, oil leaks, coolant intrusion, timing errors, and physical impacts all contribute to converter failure. Torque converters face similar risks when installers overlook fluid quality, seating, or electrical connections. Understanding these factors allows technicians and drivers to minimize risk and extend converter life. Regular inspections, correct installation methods, and prompt repairs ensure optimal emission performance.