Вступ

Modern engine designers face immense pressure to reduce toxic emissions. The transition toward the 2026 environmental standards requires sophisticated hardware. For many decades, the трикомпонентний каталітичний нейтралізатор served as the primary solution for gasoline engines. However, diesel engines present unique challenges. Diesel exhaust contains high levels of particulate matter and nitrogen oxides. Engineers cannot rely on a single трикомпонентний каталітичний нейтралізатор to handle these pollutants. Instead, they utilize specialized components like the Diesel Oxidation Catalyst (DOC) and Selective Catalytic Reduction (SCR). These technologies target specific chemical compounds in the exhaust stream. Choosing between DOC and SCR is rarely a simple “either-or” decision today. Most modern heavy-duty vehicles integrate both into a comprehensive aftertreatment string.

The Evolution of the Three Way Catalytic Converter Concept

The automotive industry first introduced the трикомпонентний каталітичний нейтралізатор in the 1970s. This device revolutionized emission control for spark-ignition engines. It simultaneously manages carbon monoxide, hydrocarbons, and nitrogen oxides. In a gasoline engine, the air-fuel ratio stays near the stoichiometric point. This balance allows the трикомпонентний каталітичний нейтралізатор to perform both oxidation and reduction in one canister.

Diesel engines operate differently. They use excess air to ensure efficient combustion. This “lean-burn” environment creates a surplus of oxygen in the exhaust. A standard трикомпонентний каталітичний нейтралізатор cannot reduce nitrogen oxides effectively in the presence of so much oxygen. Therefore, diesel engineers split the functions of the трикомпонентний каталітичний нейтралізатор into separate stages. The DOC takes over the oxidation duties. The SCR handles the reduction of nitrogen oxides. This modular approach ensures that each pollutant meets the strict 2026 limits.

Understanding the Diesel Oxidation Catalyst (DOC)

The DOC serves as the first stage in a diesel exhaust system. It functions as a specialized version of the трикомпонентний каталітичний нейтралізатор optimized for diesel cycles. The internal structure features a ceramic or metallic honeycomb substrate. Manufacturers coat this substrate with precious metals. Platinum and palladium are the most common choices.

When hot exhaust gases pass through the DOC, a chemical reaction occurs. The precious metals act as catalysts. They facilitate the oxidation of carbon monoxide (CO) into carbon dioxide (CO2). They also convert unburnt hydrocarbons (HC) into water vapor and CO2. This process mirrors the oxidation half of a traditional трикомпонентний каталітичний нейтралізатор. The DOC also plays a vital role in managing the soluble organic fraction of particulate matter. By burning these heavy hydrocarbons, the DOC reduces the total mass of soot leaving the engine.

The Role of Selective Catalytic Reduction (SCR)

The SCR system represents a more complex technological leap. While a трикомпонентний каталітичний нейтралізатор uses the exhaust gases themselves to trigger reactions, the SCR requires an external agent. This agent is typically Diesel Exhaust Fluid (DEF), which consists of a urea solution.

The SCR process begins with the injection of DEF into the exhaust pipe. The heat of the exhaust decomposes the urea into ammonia (NH3). This mixture then enters the SCR catalyst brick. Inside, the ammonia reacts with nitrogen oxides (NOx). The catalyst facilitates a reduction reaction. This reaction transforms the toxic NOx into harmless nitrogen gas (N2) and water (H2O). The SCR is incredibly efficient. High-quality systems can remove over 90% of NOx from the exhaust stream. This capability is essential for meeting the latest Euro VI and Tier 4 Final standards. Without SCR, diesel engines would struggle to survive in the modern regulatory landscape.

Technical Comparison: DOC vs. SCR

The following table provides a detailed look at the specifications and operational requirements of both systems.

| Функція | Diesel Oxidation Catalyst (DOC) | Селективне каталітичне відновлення (SCR) |

|---|---|---|

| Primary Chemical Goal | Oxidation of CO and Hydrocarbons | Зменшення викидів оксидів азоту (NOx) |

| Active Catalyst Metals | Platinum, Palladium | Vanadium or Zeolites (Iron/Copper) |

| External Reagent Required | Жоден | Diesel Exhaust Fluid (DEF / Urea) |

| Maintenance Level | Very Low (Passive system) | Moderate (Fluid refills and dosing maintenance) |

| Installation Complexity | Low (Single canister) | High (Requires tanks, pumps, and injectors) |

| Thermal Operating Window | 200°C to 450°C | 250°C to 500°C |

| Service Life | Often matches engine lifespan | Dependent on dosing system health |

| Equivalent Component | Oxidation stage of a трикомпонентний каталітичний нейтралізатор | Reduction stage of a трикомпонентний каталітичний нейтралізатор |

Thermal Dynamics and Substrate Efficiency

The efficiency of any трикомпонентний каталітичний нейтралізатор or diesel catalyst depends on heat. Catalysts require a specific “light-off” temperature to begin chemical reactions. If the exhaust is too cold, the metals remain inactive. The DOC typically lights off at lower temperatures than the SCR.

Engineers often place the DOC as close to the engine manifold as possible. This positioning captures the maximum heat from combustion. The DOC actually generates its own heat through exothermic reactions. When it oxidizes hydrocarbons, the temperature of the exhaust gas rises. This temperature boost is critical for the components located further down the tailpipe. For example, the Diesel Particulate Filter (DPF) needs high temperatures to burn off trapped soot. The SCR also performs better when the DOC provides pre-heated exhaust. This thermal synergy ensures that the entire system functions correctly even during cold starts or low-load operation.

Choosing the Best Technology for Your Engine

Selecting the right technology depends on your specific operational environment and regulatory requirements. You must evaluate your priorities regarding cost, space, and compliance.

When to Choose the DOC Technology

The DOC is the ideal choice for simpler applications. You should prioritize the DOC if you operate in a region with less stringent NOx regulations. Many older engines or stationary generators benefit from DOC retrofits. The DOC is compact and does not require a complex dosing system. It fits into tight engine compartments where an SCR tank would not. Since the DOC has no moving parts or sensors, it requires almost zero maintenance. It is a “fit and forget” solution for basic pollution control. It brings the engine closer to the performance of a modern трикомпонентний каталітичний нейтралізатор without the logistical headache of DEF.

When to Choose the SCR Technology

The SCR is mandatory for high-performance compliance. If your vehicle must meet the 2026 Euro VI or Tier 4 standards, you cannot avoid SCR. These regulations set NOx limits so low that only selective reduction can achieve them. SCR is the preferred choice for heavy-duty trucking and construction equipment. One major advantage of SCR is fuel economy. When an engine uses SCR, engineers can tune the combustion for maximum efficiency. Efficient combustion naturally produces more NOx but less soot. The SCR then cleans up the NOx later in the exhaust stream. This often results in a 3% to 5% improvement in fuel economy compared to engines using only Exhaust Gas Recirculation (EGR).

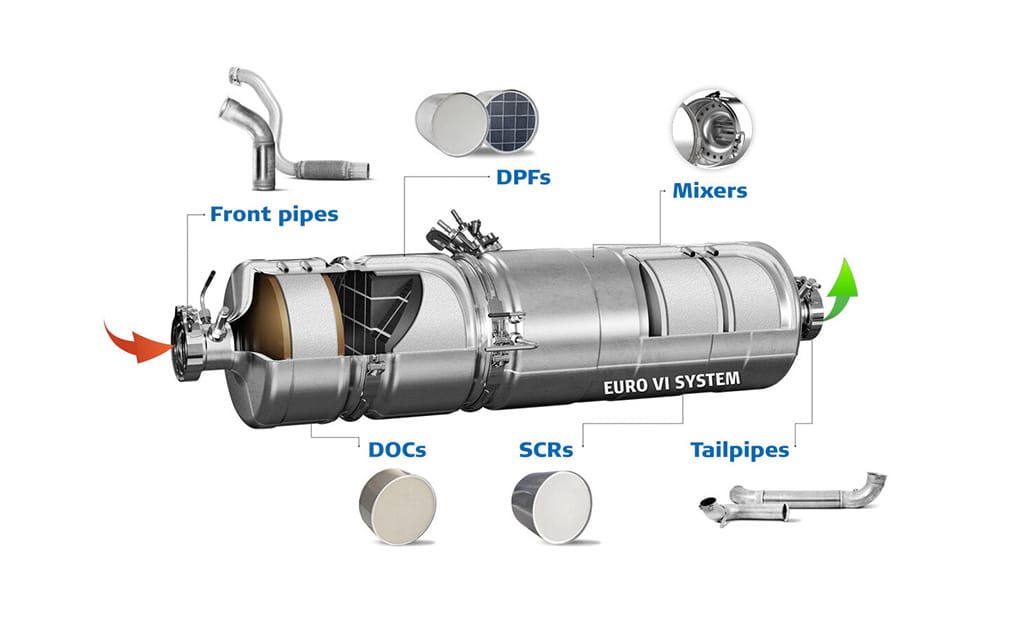

The 2026 Industry Standard: The Integrated System

As we move toward 2026, the debate is no longer about DOC vs. SCR. The industry has adopted an integrated “System Approach.” This approach combines multiple technologies into a single aftertreatment housing. This configuration mimics the comprehensive nature of a gasoline трикомпонентний каталітичний нейтралізатор but handles the unique chemistry of diesel.

The standard 2026 aftertreatment string follows a specific order:

- The DOC: This component sits at the front. It removes CO and HC while increasing exhaust temperature.

- The DPF: The Diesel Particulate Filter sits in the middle. It traps physical soot particles. It uses the heat from the DOC to perform “regeneration” and clean itself.

- The SCR: The SCR sits at the end of the line. It receives the clean, hot exhaust and removes the NOx.

This chain of components ensures that the vehicle emits only nitrogen, water, and carbon dioxide. This integrated system is more effective than any single трикомпонентний каталітичний нейтралізатор ever produced.

Substrate Materials in Modern Catalysts

The heart of the catalyst is the substrate. Most DOC and SCR systems use cordierite, a type of ceramic. Cordierite withstands high temperatures and resists thermal shock. Manufacturers extrude this material into a honeycomb shape. This shape provides a massive surface area in a small volume.

A single DOC brick can have thousands of channels. This design ensures that every molecule of exhaust gas touches the catalyst metals. In recent years, metallic substrates have gained popularity for high-performance applications. Metallic honeycombs have thinner walls than ceramic versions. Thinner walls mean less backpressure for the engine. They also heat up faster. Rapid heating allows the system to reach its “light-off” temperature sooner after a cold start. Whether using ceramic or metal, the goal remains the same: maximize contact between the gas and the catalyst. This is the same principle used in the design of every трикомпонентний каталітичний нейтралізатор.

The Impact of Engine Oil on Catalyst Longevity

Many operators overlook the connection between engine oil and catalyst health. The exhaust system is not physically connected to the oil galleries. However, the combustion process links them. A small amount of engine oil always passes the piston rings and burns in the combustion chamber. The residue of this burned oil enters the DOC and SCR.

Standard engine oils contain additives like phosphorus, sulfur, and sulfated ash (SAPS). These chemicals are excellent for lubricating engine parts but “poison” catalysts. Phosphorus coats the precious metals in the DOC. It forms a chemical barrier that prevents the exhaust from reaching the platinum. Sulfur can contaminate the active sites in an SCR catalyst. Over time, this poisoning reduces the efficiency of the system. It can trigger dashboard warning lights and force the engine into “limp mode.”

Щоб захистити свою трикомпонентний каталітичний нейтралізатор or DOC, you must use Low-SAPS oils. These lubricants meet ACEA C1-C4 or E6/E9 specifications. They use different chemical additives that do not damage the catalyst bricks. Using the correct oil is the cheapest way to ensure your emission system lasts for the life of the vehicle.

Advanced Diagnostics for Aftertreatment Systems

Modern SCR and DOC systems rely on a network of sensors. These sensors monitor the health of the catalyst in real-time. Pressure sensors measure the “delta P” or pressure drop across the DOC and DPF. If the pressure is too high, it indicates a clog.

NOx sensors sit at the inlet and outlet of the SCR. They calculate the efficiency of the NOx conversion. If the outlet sensor detects too much NOx, the computer increases the DEF dosing. If the efficiency still fails to improve, the system identifies a failing catalyst. This level of monitoring is far more advanced than the oxygen sensors found in a typical трикомпонентний каталітичний нейтралізатор. For fleet managers, these diagnostics provide valuable data. They allow for predictive maintenance before a small issue becomes a total system failure.

Environmental Awareness and Global Trends

The shift toward DOC and SCR reflects a global increase in environmental awareness. Governments in Europe, North America, and Asia are harmonizing their standards. The goal is to eliminate the “diesel smudge” that once characterized heavy transport.

Innovation continues to drive the industry forward. We are now seeing the development of “SCR-on-Filter” (SCRoF) technology. This combines the SCR coating with the DPF substrate. This integration saves weight and space. It also allows the SCR to heat up faster. Such advancements show that the spirit of the трикомпонентний каталітичний нейтралізатор lives on in more complex diesel systems. These technologies allow the diesel engine to remain a viable, clean option for global logistics.

Troubleshooting Common Catalyst Issues

Even the best systems can encounter problems. Most DOC issues stem from “face plugging.” This happens when excessive soot or oil ash covers the front of the honeycomb. You can often fix this by running the engine at high loads to burn off the deposits.

SCR systems face different challenges. “Crystallization” is a common problem in cold climates. If the DEF does not atomize correctly, it can form solid urea deposits inside the pipe. These crystals block the exhaust flow. To prevent this, modern SCR systems include heaters for the DEF tanks and lines. Regular maintenance of the DEF filter and injector nozzle is essential. If you treat your SCR with the same care as your engine, it will remain reliable for years.

Висновок

The choice between DOC and SCR depends on your specific goals for 2026. The DOC provides a robust, simple solution for oxidizing harmful gases. It acts as the diesel equivalent of the oxidation stage in a трикомпонентний каталітичний нейтралізатор. The SCR provides the advanced chemical reduction necessary to meet modern NOx limits. While the DOC is cheaper and easier to maintain, the SCR offers superior environmental performance and better fuel economy for heavy-duty applications. In the modern era, these technologies usually work together. They form a powerful defense against air pollution. By choosing high-quality catalysts and compatible lubricants, you protect both the environment and your mechanical investment.