تعارف

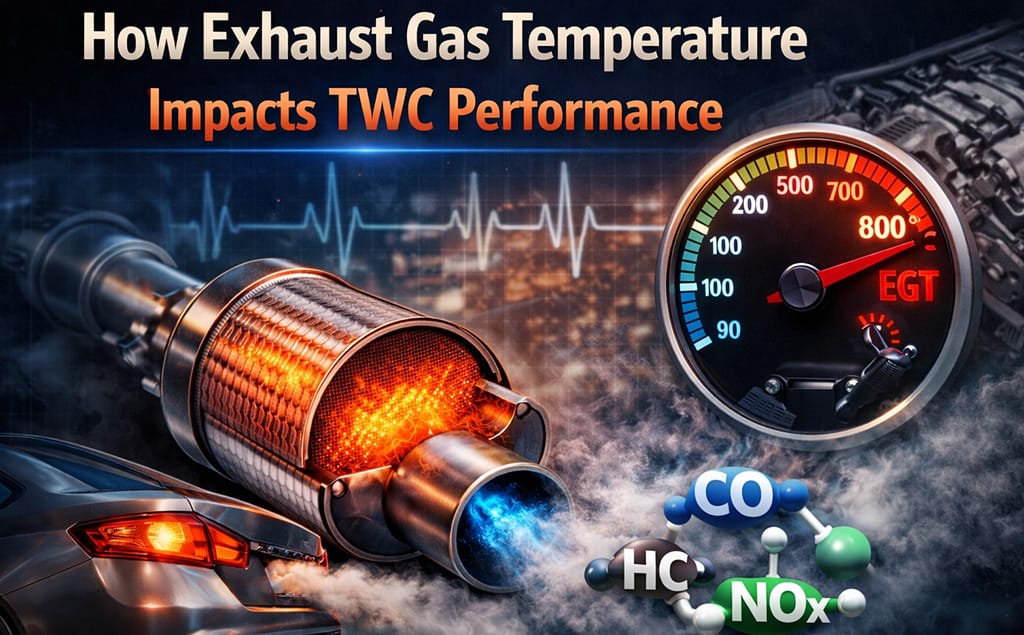

Automotive engineers prioritize the efficiency of the three way catalytic converter to meet modern environmental standards. Global regulations like the European Green Deal and EURO 7 demand nearly zero emissions from combustion engines. Most gasoline vehicles rely on the three way catalytic converter to neutralize toxic pollutants. This device converts carbon monoxide, hydrocarbons, and nitrogen oxides into harmless substances. However, the system requires specific thermal conditions to function correctly. Exhaust gas temperature serves as the primary driver of this efficiency. This article explores how temperature fluctuations impact the three way catalytic converter. We analyze the chemical shifts during cold starts and high-load operations.

The Fundamental Role of the Three Way Catalytic Converter

The three way catalytic converter stands as the most critical component in a gasoline exhaust system. It targets three specific pollutants simultaneously to protect air quality. First, it reduces nitrogen oxides into elemental nitrogen and oxygen. Second, it oxidizes carbon monoxide into carbon dioxide. Third, it oxidizes unburnt hydrocarbons into water and carbon dioxide. Engineers design the internal structure with a ceramic honeycomb substrate to maximize surface area. A washcoat containing precious metals covers this substrate. These metals usually include Platinum, Palladium, and Rhodium. The chemical reactions occur on these metallic surfaces. However, the catalyst requires a specific environment to succeed. The air-fuel ratio must stay near the stoichiometric point.

Chemical Mechanisms within the Three Way Catalytic Converter

The internal chemistry of a three way catalytic converter relies on precise thermal activation. Each pollutant requires a specific energy level to transform into a harmless gas. Oxidation reactions for carbon monoxide and hydrocarbons generate heat. This heat helps maintain the internal temperature of the device. Reduction reactions for nitrogen oxides require specific active sites on Rhodium particles. When the temperature is ideal, the three way catalytic converter achieves a conversion rate of up to 98%. The precious metals facilitate the breaking of molecular bonds efficiently. Oxygen storage components, like Ceria, manage oxygen levels during minor air-fuel fluctuations. This storage capacity allows the three way catalytic converter to function even when the engine transitions between lean and rich states.

Low Temperature Challenges and the Cold Start Problem

Cold starts represent the most vulnerable period for vehicle emissions. When you start a cold engine, the three way catalytic converter matches the ambient temperature. In this state, the catalyst is “cold” and remains inactive. Engineers call the transition point the “light-off” temperature.

The Light-Off Threshold

Most three way catalytic converter units require a temperature between 250°C and 300°C to begin functioning. Before reaching this threshold, pollutants pass through the exhaust pipe untreated. Real-world data shows that a significant portion of a vehicle’s total trip emissions occurs during the first few minutes. Modern engines produce less waste heat, which makes reaching this temperature harder.

Transient Driving Conditions

City driving often creates thermal instability for the three way catalytic converter. Frequent stops and idling allow the exhaust gas temperature to drop significantly. If the temperature falls below the light-off limit, the catalyst “extinguishes.” This leads to a spike in carbon monoxide and hydrocarbon emissions. Hybrid vehicles face an even greater challenge. Their engines turn off frequently, which allows the three way catalytic converter to cool down.

High Temperature Risks and Thermal Aging

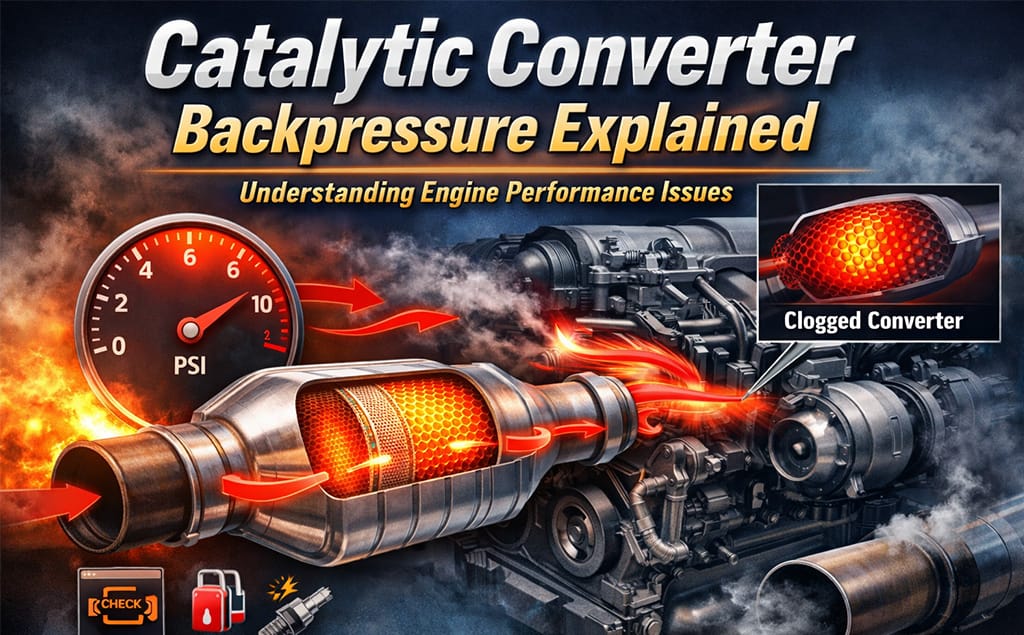

Excessive heat poses a different threat to the three way catalytic converter. While heat activates the catalyst, extreme temperatures cause structural degradation. Temperatures above 800°C trigger several negative processes.

Molecular Sintering and Surface Area Loss

High heat causes precious metal particles to migrate and clump together. This process is called sintering. Sintering reduces the effective surface area of the Platinum or Palladium inside the three way catalytic converter. A smaller surface area means fewer sites for chemical reactions. Over time, sintering permanently lowers the efficiency of the device.

Loss of Oxygen Storage Capacity

Ceria and Zirconia in the washcoat provide oxygen storage for the three way catalytic converter. Extreme heat alters the crystalline structure of these materials. When the support structure collapses, the catalyst loses its ability to store oxygen. This loss prevents the three way catalytic converter from balancing the exhaust chemistry during rapid acceleration.

Support Damage and Nitrous Oxide Formation

Extreme thermal stress can melt the ceramic substrate of the three way catalytic converter. In severe cases, the entire honeycomb structure collapses. This creates a physical blockage in the exhaust system. Additionally, very high temperatures may promote the formation of Nitrous Oxide. This gas is a potent greenhouse gas that engineers strive to eliminate.

Comparative Data for Thermal Management Materials

The following table compares the properties of different materials used in Thermal Energy Storage Systems to protect the three way catalytic converter.

| Material Type | Phase Change Temp (°C) | Thermal Conductivity | Impact on TWC Efficiency |

|---|---|---|---|

| PCM H430 | 430 | اعلی | Maximizes light-off speed |

| Metallic Alloys | 500+ | Very High | Stabilizes high-load heat |

| Paraffin Wax | 50-70 | کم | Ineffective for TWC |

| Salt Hydrates | 100-250 | درمیانہ | Provides minor pre-heating |

Role of Phase Change Materials in Modern After-treatment

Engineers now look toward Phase Change Materials to solve temperature instability. A Thermal Energy Storage System acts as a thermal buffer for the three way catalytic converter. These systems reside between the turbocharger and the catalyst.

How Thermal Energy Storage Systems Function

The Phase Change Material stores thermal energy when the exhaust gas is hot. When the engine load drops, the material releases this stored heat. This process maintains the three way catalytic converter within its optimal operating window. It acts like a battery for heat energy.

Enhancing the Light-Off Process

A thermal storage unit prevents the three way catalytic converter from cooling down during short stops. For instance, if a driver stops for 15 minutes, the storage material keeps the catalyst warm. Upon restarting, the three way catalytic converter is already at or near the light-off temperature. This eliminates the “cold start” emission spike effectively.

Analysis of the 1.5 TSI EVO Engine Model

Recent studies used a 1-D turbocharged gasoline engine model to test these theories. The research focused on the VW 1.5 TSI EVO engine. Researchers integrated a thermal storage unit into the exhaust path. They tested three different materials to find the most effective solution for the three way catalytic converter.

Improving Emission Performance

The study revealed significant improvements for the three way catalytic converter. The PCM H430 material performed the best in the simulation. This material reduced cumulative Carbon Monoxide emissions by 8.2%. It also reduced Hydrocarbon emissions by 10.6% during the standard drive cycle. These numbers prove the value of thermal stabilization.

Fuel Consumption Benefits

The storage unit also impacts fuel economy. By keeping the three way catalytic converter warm, the engine does not need to use “rich” fuel mixtures for heating. This optimization saves fuel over the vehicle’s life. Although the system adds initial cost, the long-term reduction in emissions and fuel usage justifies the investment.

Optimal Operating Windows for the Three Way Catalytic Converter

Maintaining a balance is the primary goal of engine control units. The computer adjusts the air-fuel ratio and ignition timing to manage heat.

- 300°C – 400°C: The transition zone where the three way catalytic converter starts to activate.

- 400°C – 800°C: The “Golden Zone” for the three way catalytic converter. Here, conversion efficiency reaches its maximum level.

- Above 850°C: The danger zone for the three way catalytic converter. Thermal aging begins to accelerate at this level.

Engineers use thermal barriers and insulation to keep the heat inside the pipe. They also use “dithering” techniques to manage oxygen levels inside the three way catalytic converter.

Strategies for Thermal Stabilization

Industry experts suggest several methods to control the environment of the three way catalytic converter:

- Insulated Exhaust Manifolds: Double-walled pipes prevent heat loss to the atmosphere.

- Electric Heating Elements: These heaters warm the three way catalytic converter before the engine starts.

- Waste Heat Recovery: Systems capture excess heat for other vehicle uses.

- Advanced Catalyst Design: Materials like Zirconia-stabilized Ceria improve the thermal durability of the three way catalytic converter.

Future Trends in Three Way Catalytic Converter Technology

The automotive industry moves toward even stricter regulations every year. Future three way catalytic converter designs will likely feature closer integration with the engine block. Close-coupled catalysts minimize the distance exhaust travels. This preserves heat and speeds up light-off. Furthermore, the use of sophisticated storage materials will become more common in hybrid vehicles. Hybrid engines frequently turn off and on, making thermal management even more vital for the three way catalytic converter.

نتیجہ

Exhaust gas temperature dictates the success of emission control systems. The three way catalytic converter remains the industry standard for cleaning gasoline exhaust. However, it relies heavily on thermal stability to function. Low temperatures during cold starts lead to untreated pollution. Conversely, extreme heat causes permanent sintering and the loss of oxygen storage capacity. Innovative technologies like the Thermal Energy Storage System offer a viable solution. By using Phase Change Materials, these systems bridge the gap between cold starts and steady-state operation. Research proves that stabilizing the temperature significantly reduces emissions. As we move toward the EURO 7 era, thermal management will define the next generation of the three way catalytic converter.