For procurement teams managing converter inventory, deciding between cleaning or replacing catalytic converters can impact margins and repurchase cycles. This article compares practical scenarios—when a cleaning makes sense, when failure calls for replacement—and what to discuss with suppliers to align warranties, pricing, and timing to your business strategy. Understanding these dynamics is crucial for optimizing your inventory management and ensuring your fleet or customer vehicles remain compliant and operational without incurring unnecessary costs or downtime.

When Cleaning Works

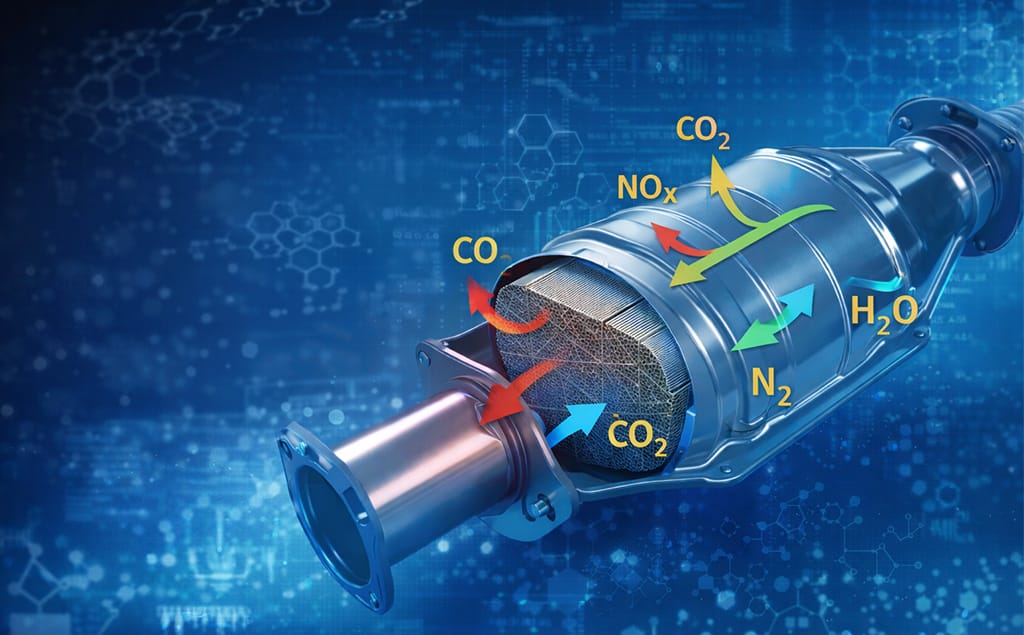

Catalytic converters are designed to be durable, but they can become clogged over time, particularly in vehicles that see a lot of stop-and-go driving or have underlying engine issues. In these situations, the converter’s substrate can become coated with carbon deposits, which restricts exhaust flow and reduces catalytic efficiency. For businesses looking for a cost-effective, short-term solution, cleaning can be a viable option, but it’s important to understand its limitations and the conditions under which it can be effective.

Cleaning is a temporary fix for a symptom, not a cure for the root cause of the problem. It is a viable strategy only when the converter is suffering from a mild to moderate buildup of carbon deposits and has no physical damage. This approach is best utilized as part of a proactive maintenance program rather than a reactive solution for a failed converter. A successful cleaning can extend the life of the unit and delay the need for a full replacement, providing a procurement team with more time to plan for a new purchase.

Chemical Soak & On-Vehicle Cleaning

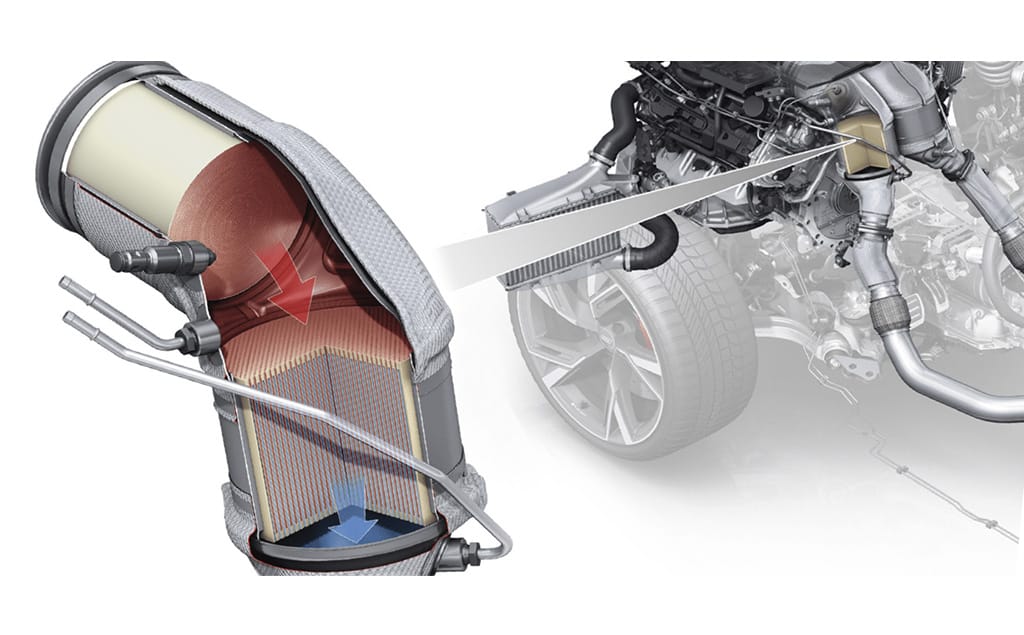

There are two primary methods for cleaning a catalytic converter: on-vehicle cleaning and off-vehicle chemical soaks. On-vehicle cleaning involves adding a specialized chemical additive to the fuel tank or directly into the intake manifold. These cleaners are designed to dissolve carbon deposits and other contaminants that are partially blocking the catalyst’s honeycomb structure. This method is the least invasive and most cost-effective, making it attractive for routine maintenance or addressing early signs of a clogged converter. However, its effectiveness is limited to minor clogs and it will not address more severe issues.

An off-vehicle chemical soak, performed by a professional, is a more intensive process. The catalytic converter is removed from the exhaust system and submerged in a powerful cleaning solution that breaks down carbon and soot. This method can be very effective at restoring exhaust flow and some of the converter’s original efficiency. For a procurement team, this option represents a lower cost per unit compared to replacement and is a good solution for vehicles with a lot of fleet mileage that are beginning to show signs of a reduction in performance. However, this method requires more labor and a technician with the right tools, so it’s not a DIY solution.

Benefits vs. Cost Savings

The main benefit of a cleaning strategy is the significant cost savings it offers compared to purchasing a new catalytic converter. The materials and labor for a professional cleaning are a fraction of the cost of a new unit, which is particularly appealing for businesses with large fleets. This can improve cash flow and allow a business to defer a capital expenditure. Furthermore, a cleaned converter can restore a vehicle’s performance and fuel efficiency, leading to additional operational savings.

However, these benefits must be weighed against the inherent risks. Cleaning is a temporary solution that does not repair a converter with a melted or degraded substrate, nor does it replace the precious metals that may have been poisoned or sintered. If the underlying engine issue—such as a faulty oxygen sensor, misfire, or rich fuel mixture—is not resolved, the converter will quickly become clogged again, rendering the cleaning a wasted effort. Procurement teams must understand that a cleaning is not a permanent fix, and a replacement will eventually be necessary.

When You Should Replace

While cleaning can offer short-term relief, there are many scenarios where a replacement is the only viable option. For a business, attempting to clean a severely damaged or failed catalytic converter can be a dangerous waste of time and money, leading to extended vehicle downtime, repeated repairs, and potential legal issues if the vehicle cannot meet emission standards. Knowing the clear signs of a failed converter is essential for making a sound business decision.

The decision to replace a converter should be made when its core function has been irreparably compromised. This can be due to a complete failure of the precious metal catalyst, which can no longer perform its chemical reactions, or due to a complete physical breakdown of the internal structure. In these cases, no amount of cleaning will restore the converter’s function, and a new part is required to get the vehicle back in service.

Severe Clogging or Failure Codes

One of the most definitive reasons for replacement is when a catalytic converter is severely clogged or melted. This is often caused by an underlying engine problem that sends an excessive amount of unburnt fuel into the exhaust, which then ignites inside the converter, melting the internal honeycomb structure. When this happens, exhaust flow is severely restricted, leading to a significant loss of engine power, overheating, and a potential “rotten egg” smell. The damage is irreversible, and cleaning will have no effect.

Another clear indicator is the presence of specific diagnostic trouble codes (DTCs), most notably P0420 (for Bank 1) or P0430 (for Bank 2). These codes mean that the vehicle’s onboard computer has detected that the catalytic converter’s efficiency is “below threshold,” indicating that the precious metals are no longer actively converting emissions. This often happens due to catalyst poisoning from contaminants or age-related degradation. In these cases, the converter has lost its chemical properties, and no amount of cleaning can restore them, making replacement a necessity for emissions compliance.

Thermal Damage or Physical Cracks

Physical damage to a catalytic converter is a non-negotiable reason for replacement. A common sign is a loud rattling sound coming from underneath the vehicle, which indicates that the internal ceramic substrate has broken apart due to physical impact or thermal shock. The broken pieces can then block exhaust flow, causing a loss of power and making the car unroadworthy. A visual inspection might also reveal a severely dented or cracked exterior shell, which suggests the internal components are likely compromised.

Additionally, a severely discolored or glowing-hot converter shell is a sign of thermal damage and catastrophic failure. This is often the result of prolonged overheating caused by unburnt fuel igniting inside the converter. This extreme heat can melt the precious metal coating and the substrate itself, rendering the converter useless. In all of these scenarios—rattling noises, cracked casings, or severe thermal damage—the structural integrity of the converter is lost, and replacement with a new, intact unit is the only safe and effective solution.

Procurement Considerations

For a procurement team, the decision between cleaning and replacing has significant strategic implications that extend beyond the repair itself. These decisions affect inventory levels, supplier relationships, warranty claims, and ultimately, the total cost of ownership for a vehicle. A proactive procurement strategy considers not only the unit cost of a new converter but also the long-term impact on the business. It is crucial to have clear communication with suppliers to manage these variables effectively.

Understanding the nuances of your supplier’s policies is just as important as understanding the technical aspects of the converter itself. A robust procurement strategy for catalytic converters involves aligning your business needs with your supplier’s capabilities, from warranty coverage to minimum order quantities, ensuring that you can respond to both predictable demand and unexpected failures without incurring significant financial risk.

Warranty Coverage & Supplier Refund Policy

One of the most critical factors for a procurement team is a converter’s warranty coverage and the supplier’s refund policy. A new catalytic converter typically comes with a warranty that covers manufacturing defects or premature failure. However, a key question to ask suppliers is whether a cleaning procedure or the use of chemical additives would void this warranty. Some suppliers may argue that cleaning constitutes a modification that invalidates the coverage. Having a clear understanding of this can protect your business from being responsible for a failed, post-cleaning converter that would have otherwise been covered.

Furthermore, it is essential to have a clear understanding of the supplier’s refund and return policies for products that fail prematurely. A converter’s failure is often a symptom of an underlying engine problem. If a new converter is installed without addressing the root cause and fails within a short period, the supplier may refuse a warranty claim, arguing that the failure was caused by the vehicle’s condition, not a defect in the part. Procurement teams must negotiate with suppliers to have a clear and fair policy for such “no fault” returns to protect their margins.

MOQ & Lead Time Implications

The choice between cleaning and replacing has a direct impact on inventory management and cash flow. For businesses operating with a cost-leadership strategy, cleaning can serve as a buffer, allowing them to stretch the life of an existing converter and avoid a purchase. This means they can maintain lower inventory levels and avoid being saddled with capital tied up in expensive replacement parts. However, relying too heavily on cleaning can lead to a reactive, rather than a proactive, procurement strategy.

When a replacement is necessary, it triggers a purchase from a supplier, which is subject to minimum order quantities (MOQs) and lead times. A procurement team must balance the need for just-in-time inventory with the reality of supplier lead times. If a supplier’s MOQ is high, a business might need to purchase more converters than immediately needed, tying up capital. By understanding the typical failure modes and lifespans of converters in their fleet, a procurement team can better forecast demand and negotiate better terms with suppliers, ensuring they have the right parts at the right time without overstocking.

Conclusion

Choosing between cleaning and replacing a catalytic converter is not just a technical decision—it’s a procurement strategy. Evaluate the condition, match your fleet needs, and coordinate with suppliers to maintain uptime and compliance while controlling costs.