Introduction

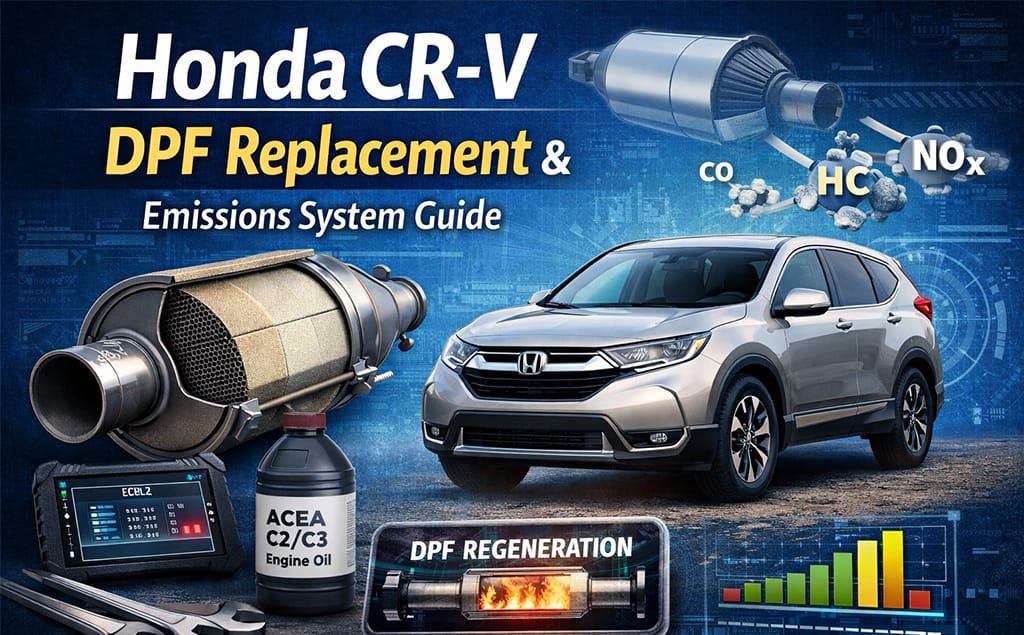

Vehicle emission systems play a critical role in modern automotive engineering. The Honda CR-V utilizes advanced technology to minimize its environmental footprint. Two primary components handle this task: the Diesel Particulate Filter (DPF) and the three way catalytic converter. While the DPF traps solid soot particles, the three way catalytic converter manages gaseous pollutants through chemical redox reactions. Maintaining these systems ensures engine longevity and regulatory compliance. This guide explores the intricate details of DPF replacement, the functional synergy with the three way catalytic converter, and the technical steps required for optimal maintenance.

The Science of Emission Control Systems

Internal combustion engines produce several harmful byproducts. Diesel engines specifically generate particulate matter and nitrogen oxides. Engineers design the exhaust system to neutralize these substances before they exit the tailpipe.

A three way catalytic converter typically serves gasoline engines. However, the principles of oxidation and reduction apply across various platforms. The three way catalytic converter contains precious metals like platinum, palladium, and rhodium. These metals act as catalysts. They facilitate the conversion of carbon monoxide into carbon dioxide. They also transform nitrogen oxides into harmless nitrogen and oxygen.

In a Honda CR-V diesel variant, the DPF works alongside oxidation catalysts. The DPF acts as a physical sieve. It captures microscopic soot. Over time, this soot accumulates. The vehicle must then perform “regeneration” to burn the soot into ash. If this process fails, the filter clogs. A clogged filter increases backpressure. This backpressure stresses the turbocharger and reduces fuel economy. Understanding the relationship between the DPF and the three way catalytic converter helps owners diagnose performance drops effectively.

Comparison of Emission Components

| Feature | Three Way Catalytic Converter | Diesel Particulate Filter (DPF) |

|---|---|---|

| Primary Function | Converts gaseous pollutants (CO, HC, NOx) | Traps solid particulate matter (Soot) |

| Active Materials | Platinum, Palladium, Rhodium | Cordierite or Silicon Carbide |

| Maintenance | Generally maintenance-free unless poisoned | Requires regular regeneration cycles |

| Common Failure | Melting or chemical “poisoning” | Physical clogging or “soot loading” |

| Vehicle Type | Primarily Gasoline (Petrol) | Primarily Diesel |

Identifying the Root Cause of Failure

You must never replace a DPF or a three way catalytic converter without a thorough investigation. Clogging is often a symptom, not the primary disease. You must identify why the filter failed to prevent the new part from suffering the same fate.

Air Intake and Boost Leaks

The engine requires a precise air-to-fuel ratio. A leak in the intercooler or intake pipes disrupts this balance. The engine then runs “rich.” A rich mixture produces excessive soot. This soot quickly overwhelms the DPF. Even a high-quality three way catalytic converter cannot process extreme levels of unburnt fuel without sustaining damage.

Sensor Inaccuracies

The Honda CR-V relies on multiple sensors. The differential pressure sensor measures the pressure drop across the DPF. If this sensor sends false data, the ECU will not initiate regeneration. Similarly, oxygen sensors monitor the efficiency of the three way catalytic converter. You must verify these sensors using a diagnostic tool like the Honda HDS.

Injector Health

Faulty fuel injectors can “dribble” fuel into the cylinder. This leads to incomplete combustion. The resulting thick smoke coats the internal structure of the three way catalytic converter and the DPF. This coating prevents the catalytic metals from contacting the exhaust gases.

Pre-Replacement Technical Protocols

Preparation determines the success of the installation. You must follow specific technical steps before you unbolt the old hardware.

Software Calibration

Modern Honda vehicles require the latest ECU firmware. Software updates often improve the logic for DPF regeneration. The manufacturer frequently tweaks the temperature thresholds and timing. Ensure your vehicle runs the most recent software version to protect your new investment.

Lubrication Requirements

Diesel engines with DPF systems require specific engine oil. You must use ACEA C2 or C3 compliant oil. These “Low SAPS” oils contain low levels of Sulfated Ash, Phosphorus, and Sulfur. Standard oils produce ash that the DPF cannot burn off. This ash permanently blocks the filter. While a three way catalytic converter is more resilient, high phosphorus levels can still “poison” its catalytic surface.

Physical Component Inspection

Inspect the mounting brackets and heat shields. Vibration can crack the ceramic substrate inside a three way catalytic converter. Ensure all exhaust gaskets are new. Reusing old gaskets leads to leaks. Leaks introduce oxygen into the exhaust stream. This oxygen confuses the sensors and triggers fault codes.

The Engineering of the Three Way Catalytic Converter

The three way catalytic converter represents a pinnacle of automotive chemistry. It performs three simultaneous tasks. First, it reduces nitrogen oxides into elemental nitrogen and oxygen. Second, it oxidizes carbon monoxide into carbon dioxide. Third, it oxidizes unburnt hydrocarbons into water and carbon dioxide.

The internal structure features a ceramic honeycomb. Manufacturers coat this honeycomb with a “washcoat.” The washcoat carries the precious metals. The three way catalytic converter requires a specific temperature range to function. This range usually starts at 250 degrees Celsius. In diesel systems, the oxidation catalyst (often paired with the DPF) helps reach these temperatures by reacting with small amounts of injected fuel.

Step-by-Step Replacement Procedure

Replacing the DPF on a Honda CR-V is a labor-intensive process. It requires specialized tools and mechanical precision.

- Vehicle Stabilization: Secure the vehicle on a professional lift.

- Sensor Removal: Carefully disconnect the temperature sensors and pressure lines. Use penetrating oil on rusted threads. These sensors are fragile.

- Exhaust Disconnection: Unbolt the DPF from the turbocharger outlet or the downpipe. On some CR-V models, the DPF and the three way catalytic converter reside in the same housing.

- Installation: Position the new unit. Align the flanges perfectly.

- Torque Specifications: Tighten all mounting bolts to approximately 42 Nm. Refer to your specific service manual for exact values. Over-tightening can snap studs. Under-tightening causes leaks.

- Sensor Re-installation: Apply a small amount of anti-seize to the sensor threads. Avoid getting anti-seize on the sensor tip.

Post-Installation and ECU Initialization

The hardware installation is only half the job. The vehicle’s computer still thinks the old, clogged filter is present.

Resetting the Adaptation Values

Use the Honda HDS (Honda Diagnostic System) or a high-level “car scanner pro.” You must tell the ECU that you installed a new DPF. This reset clears the “soot load” memory. If you skip this step, the engine may remain in “limp mode.”

Forced Regeneration Cycle

Perform a controlled forced regeneration. This process initializes the filter. The ECU will increase the idle speed and retard the injection timing. This raises the exhaust temperature significantly. The system then verifies that the pressure drop across the new filter matches factory specifications.

Sensor Adaptation

Adapt the new differential pressure sensor to the ECU. The computer must learn the “zero point” of the new sensor. This ensures accurate monitoring during future drives.

Why Professional Expertise is Vital

The complexity of the Honda CR-V emission system makes DIY replacement risky. Small errors lead to expensive consequences.

Risks of Incorrect Programming

If you do not reset the ECU correctly, the car might attempt to clean a filter that is already clean. Or, it might fail to protect the new filter from high-pressure spikes. Incorrect programming can lead to thermal runaway. This can melt the internal substrate of the three way catalytic converter.

Specialized Tooling

Standard OBD-II readers cannot perform forced regenerations. You need dealer-level software. Furthermore, professional shops use thermal imaging to check for hotspots. They also use smoke machines to find tiny intake leaks.

Environmental and Legal Compliance

Tampering with a DPF or a three way catalytic converter is illegal in many jurisdictions. Professionals ensure that the replacement parts meet OEM standards. This keeps your vehicle legal for road use and emissions testing.

Advanced Troubleshooting: Analyzing Exhaust Backpressure

Excessive backpressure ruins engine performance. If the DPF or the three way catalytic converter blocks the flow, the turbocharger cannot spin freely. This leads to “turbo lag” and eventual bearing failure. Mechanics use a pressure gauge to measure the “inches of water” or “PSI” before and after the filter.

A healthy three way catalytic converter should show minimal resistance. A DPF will show a slight pressure increase, which varies based on the soot load. If the pressure exceeds 1.5 PSI at idle, the filter requires immediate attention.

Emission System Maintenance Data

| Maintenance Task | Frequency | Impact on Three Way Catalytic Converter |

|---|---|---|

| Oil Change (ACEA C2/C3) | Every 10,000 miles | Prevents metal “poisoning” |

| Software Update Check | During annual service | Optimizes combustion efficiency |

| Fuel System Cleaning | Every 20,000 miles | Reduces soot and hydrocarbon buildup |

| Highway Driving (30+ mins) | Weekly | Enables passive DPF regeneration |

| Sensor Calibration Check | Every 50,000 miles | Ensures accurate air-fuel ratios |

Driving Habits and Their Impact

Your driving style directly affects the lifespan of the DPF and the three way catalytic converter. Short city trips are the primary enemy. In short trips, the exhaust never reaches the “light-off” temperature. The three way catalytic converter remains inactive. Soot builds up in the DPF without any chance of passive burning.

To maintain your Honda CR-V, you must drive on the highway regularly. Aim for at least 20 minutes at sustained speeds above 50 mph. This creates enough heat to keep the system clean. It also ensures the three way catalytic converter operates at peak efficiency.

Conclusion

The Honda CR-V DPF and three way catalytic converter are essential for a clean and powerful engine. Replacing these components requires more than just mechanical skill. You must diagnose the original failure, use the correct materials, and perform precise software calibrations. Professional technicians provide the tools and knowledge necessary to protect your engine from permanent damage. By following strict maintenance protocols and using quality parts, you ensure your vehicle remains efficient for years to come. Regular monitoring of soot levels and sensor health prevents the high costs associated with complete system failure.