Introduction

A three way catalytic converter relies on a precisely balanced air-fuel mixture to convert harmful exhaust gases into safer compounds. The oxygen sensor, or lambda sensor, plays a critical role in this process. It detects the level of oxygen in the exhaust stream and sends real-time feedback to the Engine Control Unit (ECU). The ECU then adjusts fuel delivery to maintain ideal combustion and maximize the efficiency of the three way catalytic converter.

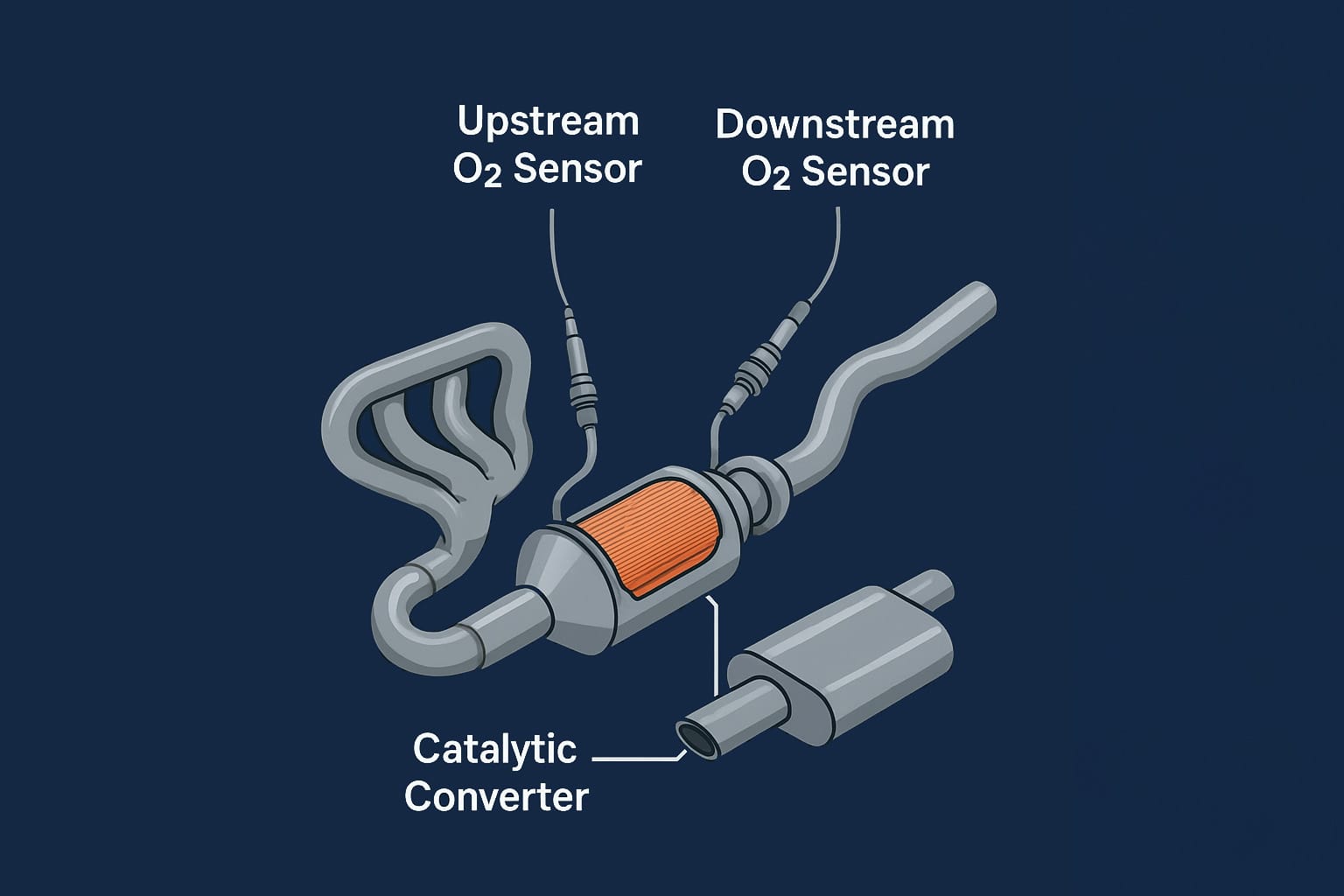

Modern engines use at least two oxygen sensors. The upstream sensor guides fuel control. The downstream sensor evaluates converter performance. Together, they create a closed-loop control system that supports stable engine operation, reliable emission reduction, and long-term catalytic converter durability.

This article explains how O2 sensors work, how they interact with the three way catalytic converter, and why they matter for emission control and overall engine health.

1. Roles of O2 Sensors in the Exhaust System

Oxygen sensors sit in the exhaust stream. Engineers place them before and after the three way catalytic converter. Each sensor performs a different task and supports the emission-control strategy in a different way.

1.1 Upstream O2 Sensor (Sensor 1)

The upstream O2 sensor sits before the catalytic converter, directly on the exhaust manifold. It measures raw exhaust gas immediately after combustion. This sensor detects how much free oxygen remains in the exhaust. It sends frequent signals to the ECU.

The ECU uses this signal to adjust fuel injection. It targets the stoichiometric ratio of 14.7:1 (air:fuel) where a three way catalytic converter performs at peak efficiency. A rich mixture has excess fuel. A lean mixture has excess air. Both conditions degrade converter performance.

1.2 Downstream O2 Sensor (Sensor 2)

The downstream O2 sensor sits after the catalytic converter. It does not control the air-fuel mixture. Instead, it monitors converter efficiency.

A healthy converter reduces oxygen fluctuations in the exhaust. When the upstream reading and downstream reading differ strongly, the system works properly. When the downstream sensor shows excessive fluctuation, the converter may be degraded or thermally damaged.

2. Closed-Loop Control in Three Way Catalytic Converter Systems

Modern engines use a closed-loop control strategy. The ECU constantly reads O2 sensor data and modifies fuel injection to maintain the correct air-fuel ratio.

2.1 Importance of Accurate O2 Sensor Signals

If O2 sensors degrade, the closed-loop system loses accuracy. The ECU may inject too much or too little fuel. That increases emissions and stresses the converter.

3. How O2 Sensors Work: The Scientific Explanation

Oxygen sensors use a ceramic element coated with precious metals. Most sensors use zirconia ceramic. This material acts like a miniature electrochemical battery when heated.

3.1 Voltage Change Based on Oxygen Level

When exhaust gas contacts the hot ceramic coating, the sensor generates a voltage:

- Low oxygen → High voltage

- High oxygen → Low voltage

The ECU interprets these changes as rich or lean conditions.

3.2 Need for Proper Temperature

The ceramic material must reach high temperature to produce accurate signals. Modern sensors include a built-in heater to reach operating temperature quickly.

3.3 Why O2 Sensors Oscillate

O2 sensors switch rapidly between high and low voltage. This oscillation helps the ECU maintain the mixture near the stoichiometric point.

4. Interaction Between O2 Sensors and the Three Way Catalytic Converter

The efficiency of a three way catalytic converter depends on precise air-fuel control. The converter performs three main reactions:

- Oxidation of hydrocarbons

- Oxidation of carbon monoxide

- Reduction of nitrogen oxides

These reactions only occur efficiently when oxygen levels remain stable.

4.1 Misfires, Carbon Buildup, and Converter Damage

A rich mixture causes unburned fuel to enter the converter. That fuel burns inside the converter and creates excessive heat. A lean mixture increases misfires and raises NOx emissions.

4.2 Why O2 Sensors Protect the Converter

O2 sensors protect the converter by preventing rich and lean conditions, reducing carbon buildup, and identifying converter failure.

5. Additional Technical Insights on Sensor Placement

Many vehicles use more than two O2 sensors. V-shaped engines place sensors on both banks.

5.1 Types of Sensor Configuration

| Engine Layout | Upstream Sensor | Downstream Sensor | Number of Converters |

|---|---|---|---|

| Inline | 1 | 1 | 1 |

| V6/V8 | 2 | 1–2 | 1 or 2 |

| Performance | 2+ | 2+ | Dual or high-flow |

5.2 When Sensors Affect Performance

A bad upstream sensor reduces engine power and fuel economy. A bad downstream sensor affects emissions testing.

6. Smart O2 Sensors and Modern Engine Technology

Modern engines use wide-band oxygen sensors. These sensors measure oxygen more accurately.

6.1 Benefits of Wide-Band Sensors

- Continuous oxygen measurement

- Precise air-fuel control

- Higher catalytic converter efficiency

- Improved engine response

- Compliance with strict emission standards

7. When and Why O2 Sensors Need Replacement

O2 sensors degrade from heat, vibration, and fuel contamination.

Signs of Sensor Failure

- Poor fuel economy

- Rough idle

- Increased emissions

- Slow reaction time

- Delayed closed-loop operation

Regular replacement protects the three way catalytic converter.

Conclusion

Oxygen sensors are essential components in any three way catalytic converter system. They measure oxygen levels, provide feedback to the ECU, and maintain the ideal stoichiometric ratio. Healthy upstream and downstream sensors support efficient combustion, protect the converter, and reduce emissions.